In the present study, the deformation behavior of aluminum alloy tube in the semi-dieless forming process developed previously by the authors was investigated. The effects of compression ratio, heating temperature and heating length on the convolution height, pitch of bellows and deformation behavior of aluminum alloy tube during the semi-dieless bellows forming process were studied.

Figure 1 shows the principle of semi-dieless metal bellows forming process. The experimental equipment was developed according to this principle. To control the location of the buckling appearing, the local heating technique and water cooling method were utilized. A high-frequency induction heating device was used to heat the metal tubes. The circulating water with a constant temperature of 20![]() was used. The Aluminum alloy (A6061) tubes with a dimension of 25(outside diameter)

was used. The Aluminum alloy (A6061) tubes with a dimension of 25(outside diameter) ![]() 2 (thickness)

2 (thickness) ![]() 800 (length) mm were used in this study.

800 (length) mm were used in this study.

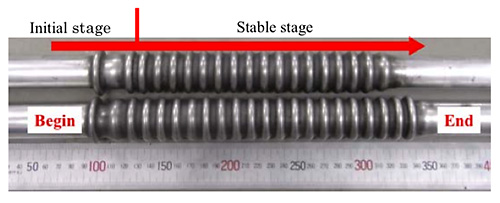

Figure 2 shows the aluminum alloy bellows produced successfully by the semi-dieless forming process with local heating technique with temperature, 400![]() and compression ratio, C(=V1/V2)=1.7. In the experiment, the forming process can be divided into two stages, initial stage and stable stage. In the present study, the drive plates started to move when the tube was heated to a certain temperature accompanied by water cooling process in the initial stage. In this initial stage, the first convolution was formed due to the different speeds of two drive plates. Because the water cooling was realized with two nozzles, the contact area between water and tube surface will be changed by the moving start of the tube. In the stable stage, the convolutions were formed continuously as the stable heating and cooling processes. The shapes of the convolutions which formed in the stable stage are the same.

and compression ratio, C(=V1/V2)=1.7. In the experiment, the forming process can be divided into two stages, initial stage and stable stage. In the present study, the drive plates started to move when the tube was heated to a certain temperature accompanied by water cooling process in the initial stage. In this initial stage, the first convolution was formed due to the different speeds of two drive plates. Because the water cooling was realized with two nozzles, the contact area between water and tube surface will be changed by the moving start of the tube. In the stable stage, the convolutions were formed continuously as the stable heating and cooling processes. The shapes of the convolutions which formed in the stable stage are the same.

Figure 3 shows the effect of compression ratio on the convolution height and pitch of aluminum alloy bellows. It can be observed that the convolution height increased with the increase of compression ratio in the range from 1.3 to 1.7. The compression ratio also showed a significant influence on the pitch (distance between the adjacent crests) of the metal bellows manufactured with semi-dieless metal bellows forming process, as shown in Fig. 3. The pitch became smaller with the increase of compression ratio in the range from 1.3 to 1.7. With the increase of compression ratio, the reduction rate of pitch became small. When the compression ratio increases to the limit value, the pitch will also decreases to the smallest.