The creep behavior in pure aluminum has been investigated by helicoid spring creep tests at strain rates, ![]() , lower than 10-10 s-1 and low temperature ranging from 0.32Tm (melting point) to 0.43Tm. And in order to discuss creep deformation mechanisms, microstructural observations before and after the helicoid spring creep tests are also carried out.

, lower than 10-10 s-1 and low temperature ranging from 0.32Tm (melting point) to 0.43Tm. And in order to discuss creep deformation mechanisms, microstructural observations before and after the helicoid spring creep tests are also carried out.

In this study, high purity aluminum (5N Al) and commercial low purity aluminum (2N Al) wires with a diameter, d = 1.6 mm were prepared. Figure 1 shows the schematic illustrations of helicoid spring creep machines. The apparatus for heated samples in Fig. 1(a) has three adjacent heaters. On the other hand, the apparatus for non-heated samples in Fig. 1(b) uses double insulation boxes to keep a constant sample temperature during creep tests. Helicoid spring specimens with a mean coil diameter, D = 18.8 mm, were prepared by winding the wire on threaded stainless steel bolts. The bolts with the wound wires were heat treated to obtain different grain sizes. Microstructures were observed by transmission electron microscopy (TEM). TEM observation area is middle parts of cross sections of the wires. The TEM observation was conducted with a JEOL JEM-2000EX/T operated at 200 kV.

Figure 2 shows examples of creep curves measured in helicoid spring creep tests for samples 5N Al (a), (b) and 2N Al (c) with different grain sizes. The creep curves are characterized by primary-stage, after which steady-state commenced due to work hardening. The curves of steady-state creep rate, ![]() s, against stress,

s, against stress, ![]() , are shown in Fig. 3. For 5N Al, the stress exponent, n, is n

, are shown in Fig. 3. For 5N Al, the stress exponent, n, is n ![]() 5 for average grain size, dg, dg > 1600

5 for average grain size, dg, dg > 1600 ![]() m, while n

m, while n ![]() 1 for dg = 24

1 for dg = 24 ![]() m. In addition, for 2N Al, the stress exponent is n = 2 for dg = 25

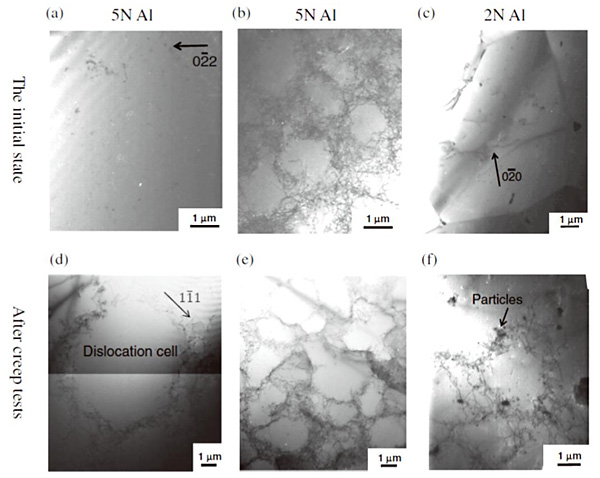

m. In addition, for 2N Al, the stress exponent is n = 2 for dg = 25 ![]() m. These facts indicate that creep behavior at low temperature and ultra-low strain rates depends on the grain sizes as well as impurity concentration. Figure 4 shows a comparison on microstructure of pure aluminum specimens after creep tests with the initial state before creep tests. Low density of dislocations in sample 5N Al with dg > 1600

m. These facts indicate that creep behavior at low temperature and ultra-low strain rates depends on the grain sizes as well as impurity concentration. Figure 4 shows a comparison on microstructure of pure aluminum specimens after creep tests with the initial state before creep tests. Low density of dislocations in sample 5N Al with dg > 1600 ![]() m and 2N Al with dg = 25

m and 2N Al with dg = 25 ![]() m. Figure 4(b) shows higher density and formation of dislocation cells in 5N Al with dg = 24

m. Figure 4(b) shows higher density and formation of dislocation cells in 5N Al with dg = 24 ![]() m. After creep test, dislocation cells composed by tangled dislocations in cell boundaries are formed with an average cell diameter of 10

m. After creep test, dislocation cells composed by tangled dislocations in cell boundaries are formed with an average cell diameter of 10 ![]() m in 5N Al with dg > 1600

m in 5N Al with dg > 1600 ![]() m (d) and 3

m (d) and 3 ![]() m in 2N Al with dg = 25

m in 2N Al with dg = 25 ![]() m (f). No remarkable change in dislocation density, dislocation cell sizes and dislocation arrangements between the non-crept (b) and the crept (e) is observed.

m (f). No remarkable change in dislocation density, dislocation cell sizes and dislocation arrangements between the non-crept (b) and the crept (e) is observed.

Based on these results, we discuss the effect of grain sizes and impurity concentration in low-temperature and low-strain rate creep behavior. We suggested that there are three kinds of creep behavior depending on grain sizes and impurity concentration at T < 0.4 Tm and ![]() < 10-10 s-1.

< 10-10 s-1.

For 5N Al with dg > 1600 ![]() m nearly the wire diameter of the spring sample, where the role of grain boundary during creep deformation can be negligible, where the stress exponent was n

m nearly the wire diameter of the spring sample, where the role of grain boundary during creep deformation can be negligible, where the stress exponent was n ![]() 5 and the activation energy was Q = 32 kJ/mol. Microstructural observation shows the formation of large cell and tangled dislocations at the cell walls. The creep deformation is consistent with low-T and low-Q dislocation creep. Because the applied stress is enough to activate the Frank-Read sources in the dislocation cells, the creep is considered occurring through the supply of dislocations inside dislocation cells creep.

5 and the activation energy was Q = 32 kJ/mol. Microstructural observation shows the formation of large cell and tangled dislocations at the cell walls. The creep deformation is consistent with low-T and low-Q dislocation creep. Because the applied stress is enough to activate the Frank-Read sources in the dislocation cells, the creep is considered occurring through the supply of dislocations inside dislocation cells creep.

For 5N Al with dg = 24 ![]() m, the stress exponent was n ~ 1 and the activation energy was Q = 15 kJ/mol. No apparent change of microstructure has been observed. The creep deformation is suggested as low-T and low-Q intrinsic grain boundary sliding.

m, the stress exponent was n ~ 1 and the activation energy was Q = 15 kJ/mol. No apparent change of microstructure has been observed. The creep deformation is suggested as low-T and low-Q intrinsic grain boundary sliding.

For 2N Al with dg = 25 ![]() m, the stress exponent was n = 2 and the activation energy was Q = 25 kJ/mol. Microstructural observations revealed dislocation emission from grain boundary, those dislocations interacting with intragranular dislocations and the formation of dislocation cells in the grains. The creep deformation is suggested as low-T and low-Q extrinsic grain boundary sliding.

m, the stress exponent was n = 2 and the activation energy was Q = 25 kJ/mol. Microstructural observations revealed dislocation emission from grain boundary, those dislocations interacting with intragranular dislocations and the formation of dislocation cells in the grains. The creep deformation is suggested as low-T and low-Q extrinsic grain boundary sliding.