Recently, porous aluminum alloys with aligned unidirectional pores have attracted a growing interest for light-weight structural materials because of the superior mechanical properties. For example, the specific strength of this kind of porous aluminum alloys does not decrease in the pore direction even with increasing porosity, because of lack of stress concentration. This study was conducted to establish a fabrication method for porous metals with aligned pores.

Aligned seven pure aluminum pipes with internal diameter of 3 mm and wall thickness of 0.5 mm were dipped into Al-4 mass% Cu melt and semi-solid slurry (Fig.1). Base metal ingots used as semi-solid slurry were fabricated by a cooling slope (Fig. 2). The specimen was cooled and solidified after holding times 0, 15 and 30 s.

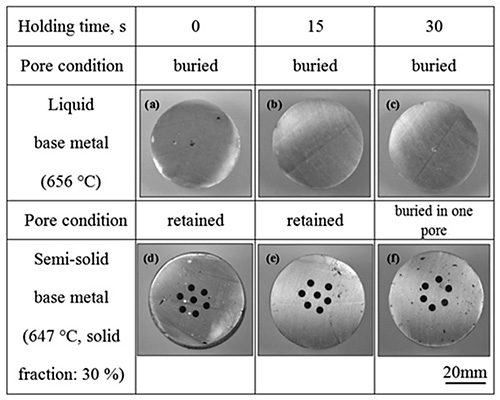

Figure 3 shows the cross-section of the fabricated samples using the liquid and semi-solid slurry of the base metal at the holding times 0, 15 and 30 s. No pore is found in the samples at any holding time when the base metal was melt. Only six pores exist in the sample at 30 s when the base metal was semi-solid slurry.

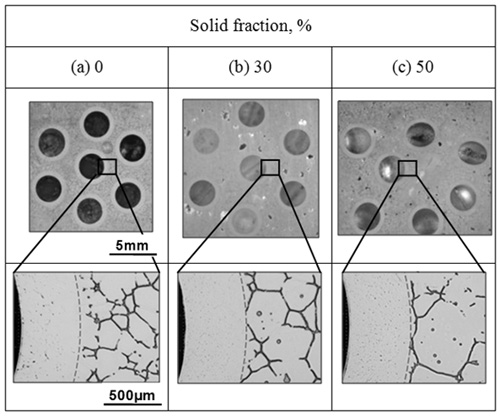

Figure 4 shows the cross-sections and the microstructures in the vicinity of the boundary between the pipes and the base metal at different solid fraction at holding time 0 s. The sample without rupturing and burying pipes (Fig.4(a)) was obtained only less than once in ten experiments using liquid base metal. The positions of pipes were shifted randomly from the initial position when the solid fraction was 50 % (Fig.4(c)). On the other hand, neither rupture nor buckling of pipes occurred in all of dipping experiments (seven times) when the solid fraction was 30 % (Fig.4(b)).

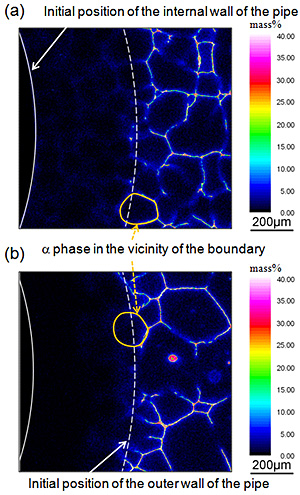

The color mapping images of Cu content measured by the EPMA analysis in the samples dipped pipes into liquid base metal (Fig. 5 (a)) and semi-solid base metal (Fig. 5 (b)) show that some Cu extended inside the initial position of the outer wall of the pipe along grain boundary.

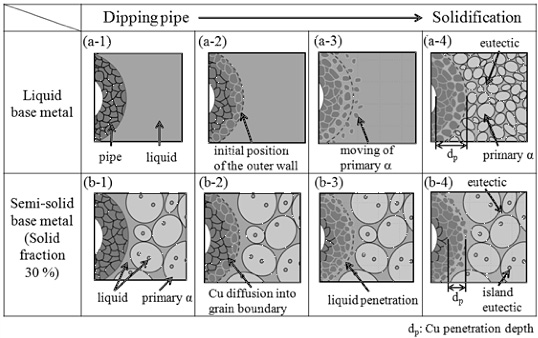

The mechanism of bonding between the pipe and the base metal can be described as shown in Fig.6. The base metal is liquid (Fig.6 (a-1)) or semi-solid with primary ![]() including eutectic liquid islands Fig.6 (b-1) just after dipping pipes. Then Cu penetrates into the pipe Fig.6 (a-2) and Fig.6 (b-2).

including eutectic liquid islands Fig.6 (b-1) just after dipping pipes. Then Cu penetrates into the pipe Fig.6 (a-2) and Fig.6 (b-2).

The following conclusions were obtained.

(1) Porous aluminum alloys with aligned unidirectional pores can be fabricated by dipping aligned aluminum pipes into a liquid base metal and semi-solid base metal and solidifying them.(2) Heat quantity from a base metal to pipes is decreased by about solid fraction, which is able to reduce the initial thickness by using semi-solid slurry for a base metal.

(3) Diffusion of Cu from a base metal to grain boundary of pipes decreases the liquidus temperature of