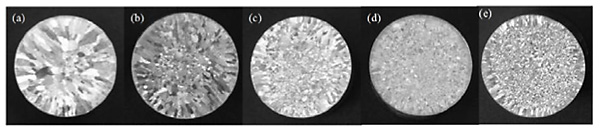

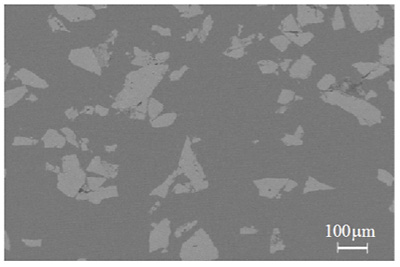

Adding grain refiners as nucleants is the most common method of refining the grain structure of aluminum alloys during the solidification processes. In this review paper, our recent studies on grain refiners containing heterogeneous nucleation sites are reviewed. Improvement of grain refining performance can be achieved by severe plastic deformation of grain refiners, since density of heterogeneous nucleation sites could be increased, as shown in Fig. 1. Another method is use of heterogeneous nucleation sites with smaller disregistry value. It is known that alloying with a certain amount of transition element causes the transformation from the DO22 type tetragonal structure of Al3Ti into high-symmetry L12 cubic structure. Since some intermetallic compounds with L12 structure have smaller disregistry values toward aluminum, one can obtain grain refiners containing heterogeneous nucleation sites with smaller disregistry value. Microstructure of novel refiner with L12 structure Al2.5Cu0.5Ti intermetallic compound particles is shown in Fig. 2.

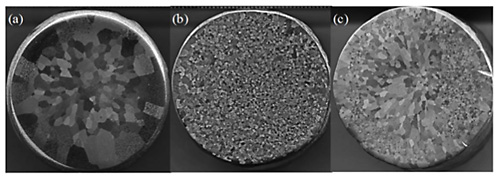

By using the novel refiner, the grain refining performance was tested, and results are shown in Fig. 3. The Al cast without refiner shown in Fig. 3 (a) has relatively larger grain size. On the contrary, it is found that the grains of Al cast are refined by novel refiner tested, as shown in Figs. 3 (b) and (c). In this way, the Al2.5Cu0.5Ti intermetallic compound particles with L12 structure can become favorable heterogeneous nucleation sites for Al cast. It is found that finer grained aluminum casts with higher mechanical properties can be fabricated using heterogeneous nucleation sites with smaller disregistry value.