The dislocation structure was analyzed in a Mg–4.98Al–1.46Ca (mass%) alloy using invisible criterion with transmission electron microscopy. Basal and non-basal segment of dislocation induced during die-casting is determined as much <a> and a few <a + c> dislocation. After the aging at 523 K for 10 h and tensile deformation at 473 K, only basal <a> dislocation can be observed. This dislocation structure is not observed in crept specimens, which support the difference in dominant strengthening mechanism between creep and tensile deformation.

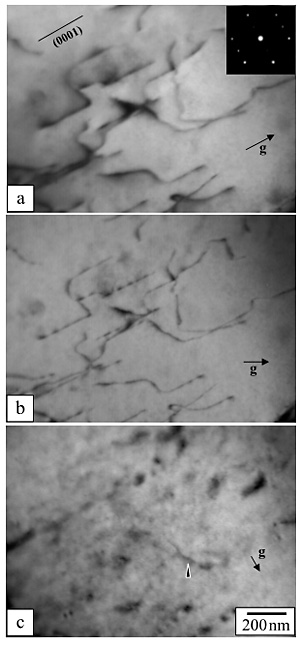

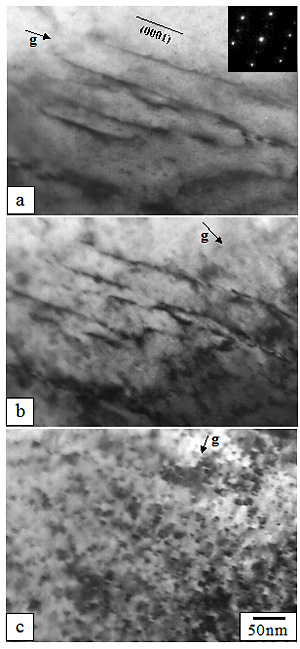

Table 1 shows the chemical composition of the Mg–5Al–1.5Ca alloy used in this study (in mass%). Table 2 shows the g · b invisibility criterion for perfect dislocations in the hexagonal close-packed crystals close to the [1-210] zone axis. Figure 1 shows the TEM bright field images of the as die-cast Mg–5Al–1.5Ca alloy, taken with B = [1-210]. The g vector is 10-10 (a), 10-11 (b) and 0002 (c), respectively. The <a + c> dislocation is indicated with an arrowhead in (c). Figure 2 shows the dislocation substructures developed after tensile test at 473 K/4.6 ![]() 10-5 s-1 for the Mg–5Al–1.5Ca alloy aged at 523 K for 10 h, taken with B = [1-210]. The g vector is 10-10 (a), 10-11 (b) and 0002 (c), respectively. The introduced strain during tensile test is 5.6%.

10-5 s-1 for the Mg–5Al–1.5Ca alloy aged at 523 K for 10 h, taken with B = [1-210]. The g vector is 10-10 (a), 10-11 (b) and 0002 (c), respectively. The introduced strain during tensile test is 5.6%.