Metallurgical Abstracts on Light Metals and Alloys vol.56

Optimization of the Surface Structure of the SiC Substrate for SiC-Ni Melt-bonding Using Simulation by Phase-Field Method

Yasushi Sasajima*, Kyohei Iwata*, Kazuki Shinozuka* and Jin Onuki**

* Institute of Quantum Beam Science, Graduate school of Science and Engineering, Ibaraki University, Hitachi 316-8511, Japan

** Emeritus Professor, Ibaraki University, Hitachi 316-8511, Japan

[Published in ECS Journal of Solid State Science and Technology, 11 (2022)124001]

https://doi.org/10.1149/2162-8777/aca51a

E-mail: yasushi.sasajima.mat[at]vc.ibaraki.ac.jp

Key Words: SiC-Ni melt-bonding, regrowth layer, interface shape control, phase field method, Gibbs-Thomson effect.

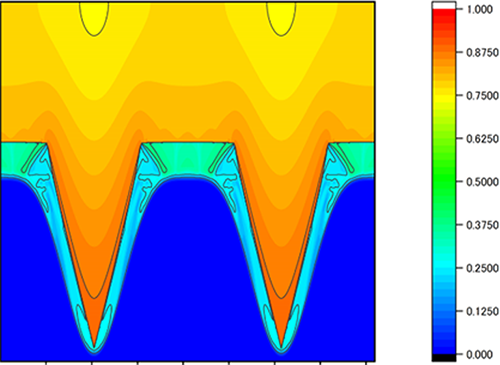

When SiC is melt-bonded with Ni electrode, a regrowth layer containing C is formed due to the dissolution of C into the molten NiSi, which deteriorates the electrical properties. We found that the regrowth layer can be suppressed by giving the surface of the SiC substrate wavy shape. The wavy-shape substrate with appropriate periodic length and amplitude lead to the suppression of regrowth layer at the bottom of the groove. The mechanism of the suppression of the regrowth layer is that the condensation of NiSi in the grooves of the substrate causes the decrease of undercooling by decreasing the equilibrium melting point. Thinner the groove is, higher the condensation of NiSi becomes, however, further thinning of the groove reduces the curvature at the bottom of the groove and increases the melting point due to the Gibbs-Thomson effect. This effect cancels the lowering of the melting point due to the NiSi condensation, making it difficult to suppress the regrowth layer. There is an optimum range of periodic length and amplitude of the substrate surface for suppressing regrowth layer. The substrate shape with a periodic length of 9.4 μm and an amplitude of 0.92 μm was most effective to suppress the regrowth layer.

NiSi concentration for 9.4µm periodic length and 2.3µm groove depth. The lengths of the x- and y-directions are 75.4µm and 4.7µm, respectively.