Metallurgical Abstracts on Light Metals and Alloys vol.56

In Situ Quantitative Measurement of Stress Distribution in Tensile Specimen Using a Detachable Mechanoluminescence Film

Kuniaki Kanamaru*, Kota Nagasao* and Hiroshi Utsunomiya**

* Shimadzu Corporation, Kyoto 604-8511, Japan

** Graduate School of Engineering, Osaka University, Osaka 565-0871, Japan

[Published in Materials Transactions, Vol. 64 (2023), 527–534.]

https://doi.org/10.2320/matertrans.MT-L2022022

E-mail: uts[at]mat.eng.osaka-u.ac.jp

Key Words: Mechanoluminescence, Finite element analysis, Aluminum alloys, Nonuniform deformation

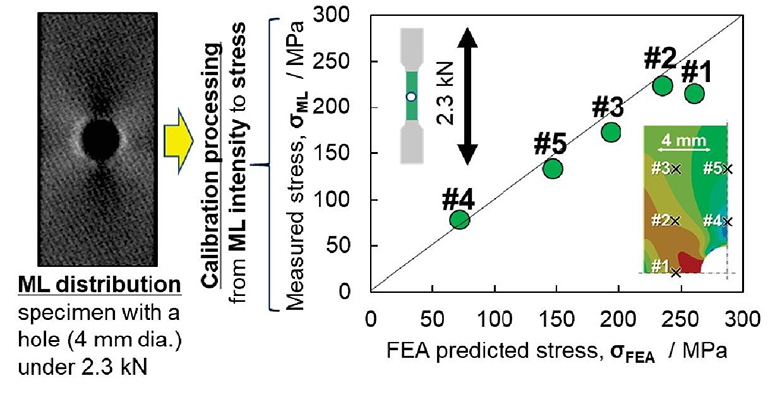

Mechanoluminescence (ML) materials, e.g., SrAl2O4:Eu2+, emit visible light when mechanical stress is applied. It was reported that the intensity of the light is in proportion to the applied von Mises stress. Therefore, acting von Mises stress can be measured from the intensity using a calibration curve. To make the ML measurements easier and more flexible, a detachable ML film has been newly developed. One surface of the base sheet was coated with detachable adhesive, while the other was coated with ~5 µm thick ML layer. Two ML films were taken from one ML sheet so that the two pieces have identical ML properties. One piece was pasted on an A6061 aluminum alloy test piece (JIS13B, t = 1.0mm) to obtain a calibration curve by the tensile test. The other piece was pasted on another A6061 test piece with a circular opening at the center to reveal the nonuniform stress distribution. The von Mises stress converted from the ML intensity showed a good agreement with the prediction by finite element analysis (FEA). It is concluded that the detachable ML film is sufficiently accurate and practical means to measure stress distribution in the target material.

Comparison of von Mises stress converted from the ML intensity with that predicted by FE analysis.