Metallurgical Abstracts on Light Metals and Alloys vol.56

Excellent strength-ductility balance of Sc-Zr-modified Al-Mg alloy by tuning bimodal microstructure via hatch spacing in laser powder bed fusion

Yusufu Ekubaru*, **, Ozkan Gokcekaya*, **, Takuya Ishimoto*, **, ***, Kazuhisa Sato****, Koki Manabe*, Pan Wang***** and Takayoshi Nakano*, **

*Division of Materials and Manufacturing Science, Graduate School of Engineering, Osaka University

**Anisotropic Design and Additive Manufacturing Research Center, Osaka University

***Aluminium Research Center, University of Toyama

****Research Center for Ultra-High Voltage Electron Microscopy and Division of Materials and Manufacturing Science, Graduate School of Engineering, Osaka University

*****Singapore Institute of Manufacturing Technology

[Published in Materials & Design, Vol. 221 (2022), 110976]

https://doi.org/10.1016/j.matdes.2022.110976

E-mail: Nakano[at]mat.eng.osaka-u.ac.jp

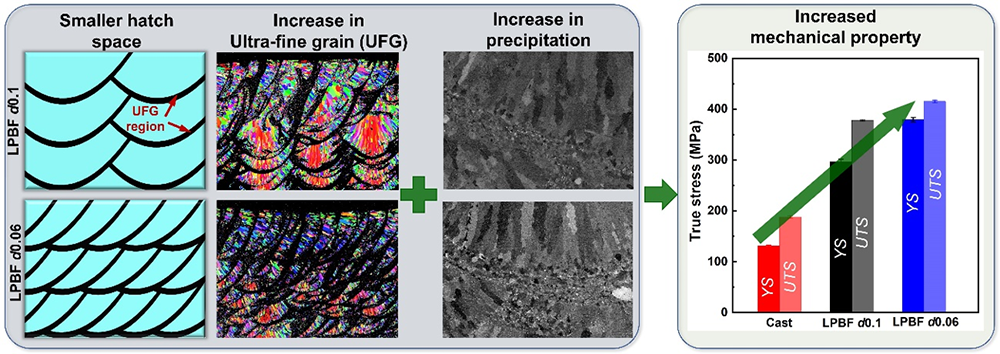

Key Words: Laser powder bed fusion, Ultrafine grain, Hatch spacing, Melt pool, Precipitation

The bimodal microstructure, which comprises ultrafine grains (UFGs) forming along the melt pool boundary and relatively coarse grains inside the melt pool, is a characteristic of the Sc-Zr-modified Al-Mg-based alloy (Scalmalloy) microstructure manufactured using laser powder bed fusion (L-PBF). Focusing on this microstructure, we study investigated the improvement in the mechanical properties of L-PBF-fabricated Scalmalloy by tailoring the volume fraction of UFGs. Our approach was to decrease the laser hatch spacing (d) from 0.1 to 0.04 mm, while the volume fraction of UFGs increased from 34.6 ± 0.6 % (d = 0.1 mm) to 59.5 ± 0.5 % (d = 0.06 mm). The tensile yield stress increased from 296 ± 9 (d = 0.1 mm) to 380 ± 6 MPa (d = 0.06 mm), while maintaining a large elongation (14.8 % ± 1.2 %). The yield stress and elongation were superior to those of the cast counterparts by 2.9 and 4.0 times, respectively. In the sample with d = 0.04 mm, pores formed owing to excessive thermal energy input. Additionally, we investigated multiple strengthening mechanisms of the as-fabricated alloy. This is the first report to improve the mechanical properties of LPBF-fabricated Scalmalloy by optimizing the track-to-track interval and tuning the UFG fraction.