Metallurgical Abstracts on Light Metals and Alloys vol.56

Effect of Scan Speed on Microstructure and Tensile Properties of Ti-48Al-2Cr-2Nb Alloys Fabricated via Additive Manufacturing

Ken Cho*, Masahiro Sakata*, Hiroyuki Y. Yasuda*, Mitsuharu Todai**, Minoru Ueda***, Masao Takeyama**** and Takayoshi Nakano*

*Graduate School of Engineering, Osaka University

**Department of Environmental Materials Engineering, Institute of Niihama National College of Technology

***Metal Technology Co. Ltd.

****Department of Metallurgy and Ceramics Science, Tokyo Institute of Technology

[Published in Materials Transactions, Vol.64 (2023), pp.1112–1118]

https://doi.org/10.2320/matertrans.MT-ME2022012

E-mail: hyyasuda[at]mat.eng.osaka-u.ac.jp

Key Words: Additive manufacturing, Titanium aluminide, Microstructure control, Mechanical properties

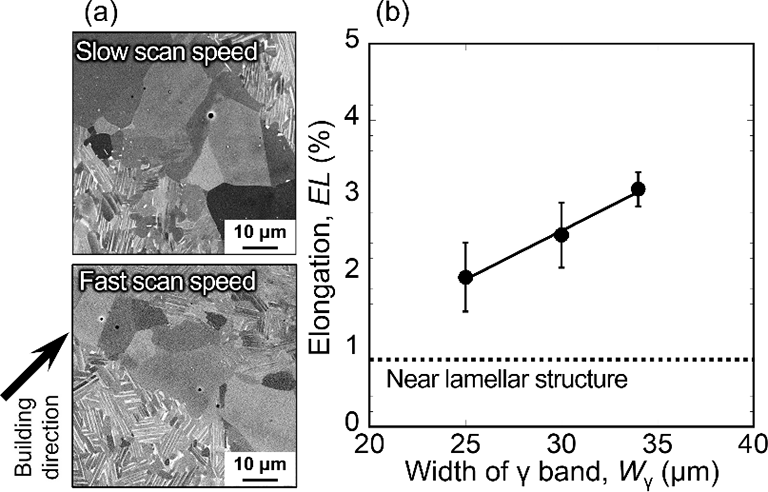

The microstructure and tensile properties of Ti-48Al-2Cr-2Nb (at.%) alloys fabricated by the electron beam powder bed fusion (EB-PBF) process were investigated with a particular focus on the effect of the scan speed of the electron beam. Homogeneous near lamellar structure composed of the α2 and γ phases was formed in the rod fabricated under the slowest scan speed. On the other hand, a layered microstructure perpendicular to the building direction comprising a duplex-like region and an equiaxed γ grain layer (γ-band) is obtained when increasing scan speeds. We observed for the first time that the width of the γ band decreases with increasing the scan speed. The near lamellar structure exhibits higher strength compared to the layered microstructure. Whereas, the rods with the layered microstructure show large ductility at room temperature. In addition, we also found that the width of the γ band has a significant influence on the tensile properties of the rods. The elongation of each rod strongly depends on the width of the γ band owing to the preferential deformation of the γ band.

The γ band of the rods fabricated at slow and fast scan speed (a) and relationship between the elongation at room temperature and the width of the γ band.