Metallurgical Abstracts on Light Metals and Alloys vol.56

Tribological Behavior of Titanium-Sintered Composites with Ring-Shaped TiN Dispersoids

Junko Umeda*, Hiroko Fujii*, Ryota Takizawa**, Takuma Teramae**, Ammarueda Issariyapat*, Shota Kariya*, Yafeng Yang***, Shufeng Li**** and Katsuyoshi Kondoh*

*Joining and Welding Research Institution, Osaka University

**Graduate School of Engineering, Osaka University

***Chinese Academy of Sciences

****School of Materials Science and Engineering, Xi’an University of Technology

[Published in Lubricants, Vol. 10 (2022) 254]

https://doi.org/10.3390/lubricants10100254

E-mail: umedaj[at]jwri.osaka-u.ac.jp

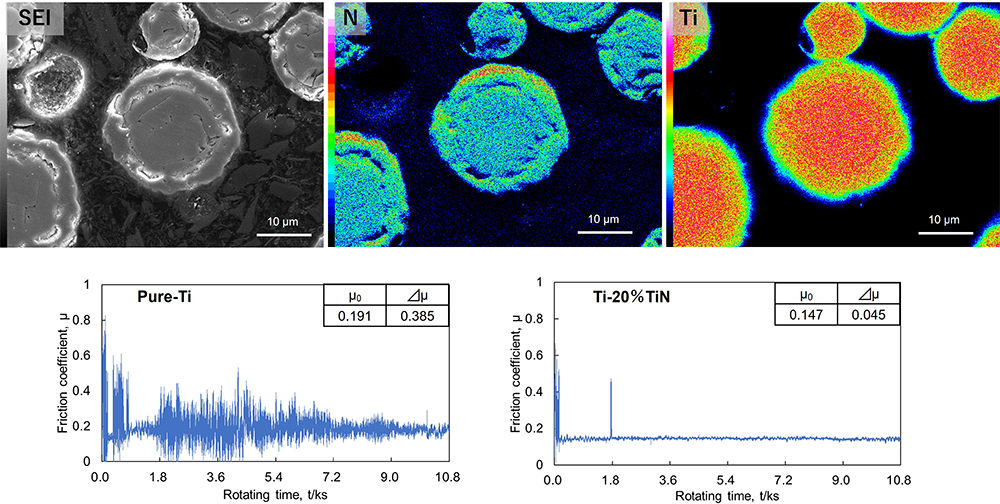

Key Words: core-shell structured TiN powder, ring-shaped TiN dispersion, tribological properties

In this study, the tribological properties of Ti matrix composites with ring-shaped TiN dispersoids were evaluated. The materials were fabricated from pre-mixed pure Ti powder and core-shell structured Ti-(N) powder, which were prepared by heat treatment at 1273 K under N2 gas. The tribological behavior of the Ti-TiN composites was studied by varying the applied load using a ball-on-disk wear test under oil lubrication conditions. The initial familiarity period of the Ti-TiN composites decreased. Subsequently, compared to the pure Ti specimen employed as a reference material, the friction coefficient was significantly lower and more stable. This is attributed to the ring-shaped, hard TiN dispersoids, which prevented the adhesion phenomenon and improved the oil film formability owing to the increase in microhardness and abrasive wear resistance of the nitrogen solid solution in the core region.

Cross-sectional SEM-EDS results of core-shell structured Ti-N powder and changes in the friction coefficient of Ti-N alloys fabricated by PM process.