Metallurgical Abstracts on Light Metals and Alloys vol.56

Ultrahigh yield strength and large uniform elongation achieved in ultrafine-grained titanium containing nitrogen

Yan Chong1, Tomohito Tsuru2, Baoqi Guo1, Reza Gholizadeh1, Koji Inoue3 and Nobuhiro Tsuji1

1 Department of Materials Science and Engineering, Kyoto University, Yoshida Honmachi, Sakyo-ku, Kyoto 606-8501, Japan

2 Nuclear Science and Engineering Center, Japan Atomic Energy Agency, Tokai-mura, Ibaraki, Japan

3 Institute for Materials Research, Tohoku University, Oarai, Ibaraki, Japan

[Published in Acta Materialia, Vol. 240 (2022), 118356.]

https://doi.org/10.1016/j.actamat.2022.118356

E-mail: nobuhiro-tsuji[at]mtl.kyoto-u.ac.jp

Key Words: Titanium; Nitrogen; Interstitial Hardening; <c+a> Dislocation; Grain Boundary Segregation.

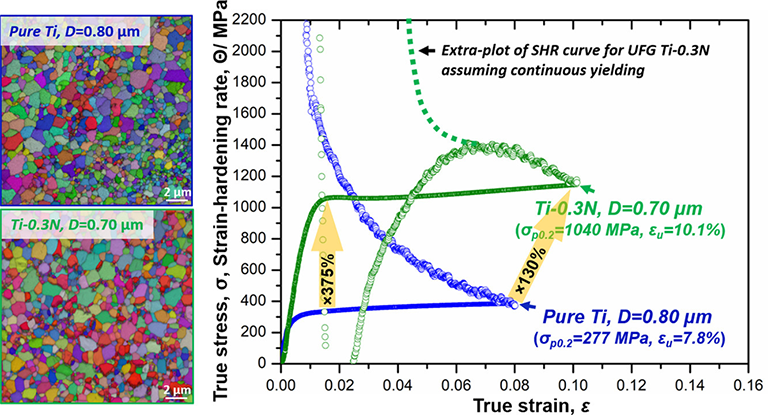

In this study, we systematically investigated the influences of nitrogen content and grain size on the tensile properties and deformation behaviors of titanium at room temperature. By high-pressure torsion and annealing, we obtained ultrafine-grained (UFG) Ti-0.3wt.%N alloy with a fully recrystallized microstructure, which combined an unprecedented synergy of ultrahigh yield strength (1.04 GPa) and large uniform elongation (10%). The hardening and strain-hardening mechanisms of Ti-0.3wt.%N alloy were comprehensively studied via deformation substructure observation and first-principles calculations. It is revealed that the contributions of nitrogen to the excellent strength/ductility balance in UFG Ti-0.3wt.%N were twofold. On one hand, nitrogen atoms inside the grains strongly impeded the motion of <a> dislocations on prismatic plane due to the shuffling of nitrogen from octahedral to hexahedral site, giving rise to a six-fold increase in the friction stress relative to pure Ti. Moreover, the greatly reduced stacking fault energy difference between prismatic and pyramidal planes in Ti-0.3wt.%N alloy facilitated an easier activation of <c+a> dislocations, which contributed to an enhanced strain-hardening rate. On the other hand, some nitrogen atoms segregated near the grain boundaries, a phenomenon discovered in α-titanium for the first time. These segregated nitrogen atoms served as an additional contributor to the high yield strength of UFG Ti-0.3wt.%N, by raising the barrier against dislocation slip transfer between grains. Our experimental and theoretical calculation work provide insights for the design of affordable high strength titanium without a large sacrifice of ductility, shedding lights on a more widespread use of this high strength to weight ratio material.

Adding 0.3%N to pure titanium enhanced both strength and ductility through increasing the strain-hardening rate due to the activation of unusual <c+a> slip systems.