Metallurgical Abstracts on Light Metals and Alloys vol.56

Concept and fabrication of beta-type titanium alloy rod with parts possessing different Young’s moduli for spinal fixation

Masaaki Nakai1, Kengo Narita2, Koichi Kobayashi3, Keisuke Sasagawa4, Mitsuo Niinomi5-8 and Kazuhiro Hasegawa9

1 Department of Mechanical Engineering, Faculty of Science and Engineering, Kindai University

2 Maruemu Works Co., Ltd.

3 School of Health Sciences, Faculty of Medicine, Niigata University

4 Department of Mechanical and System Engineering, Niigata Institute of Technology

5 Institute for Materials Research, Tohoku University

6 Department of Materials and Manufacturing Science, Graduate School of Engineering, Osaka University

7 Department of Materials Science and Engineering, Faculty of Science and Technology, Meijo University

8 Department of Chemistry and Materials Engineering, Faculty of Chemistry, Materials and Bioengineering, Kansai University

9 Niigata Spine Surgery Center

[Published in Materials Transactions, Vol. 64 (2023), pp.147–154]

https://doi.org/10.2320/matertrans.MT-MLA2022019

E-mail: nakai[at]mech.kindai.ac.jp

Key Words: Biomedical titanium alloy, Heat treatment, Young’s modulus, Implant, Spinal fixation

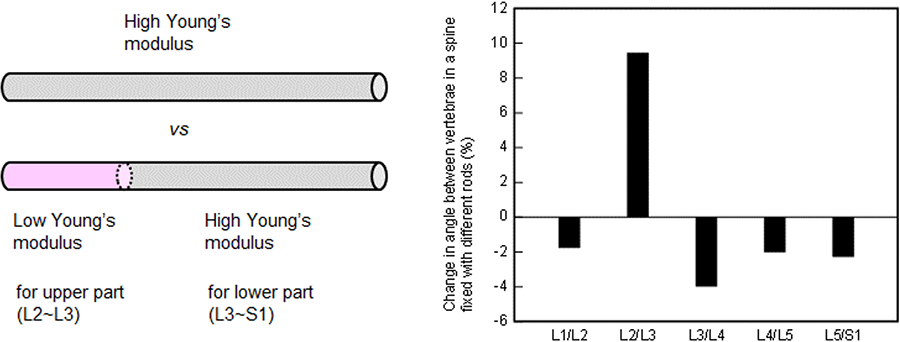

This paper proposes the concept and fabrication process of titanium alloy rods for spinal fixation. A part of rod for fixing the lower side of the lumbar vertebra is strengthened, while the other part for fixing the upper side has low stiffness. The results obtained by finite element analysis reveal that a rod with partially lowered Young’s modulus has higher flexibility and fixity compared with a rod possessing high Young’s modulus throughout. Using Ti-29Nb-13Ta-4.6Zr alloys with oxygen contents of 0.2 and 0.4% as the model alloys, rods with partially different Young’s moduli were fabricated by aging treatment at 723 K, followed by partial heating up to above the β-transus temperature and quenching by high-frequency induction heating (IH-treatment). A single β-phase, which has low Young’s modulus, is obtained by IH-treatment and has lower strength. With regard to the as-aged parts, the precipitated condition of the α-phase can be changed by varying the aging time. The obtained Young’s modulus and strength reflect this change. Near the boundary between the as-aged and IH-treated parts, the hardness is gradually changed, and it is possible to gradually soften the material from the as-aged part to the IH-treated part.

Change in angle between vertebrae in a spine fixed with rods possessing Young’s modulus of 110 GPa throughout and those possessing Young’s moduli of 110 GPa in S1~L3 part and 60 GPa in L3-L2 part, when movable displacement is applied during daily activities.