Metallurgical Abstracts on Light Metals and Alloys vol.56

Joining of Porous Aluminum and Aluminum Dense Plate by Press Working during Foaming

Shun Otsuka*, Yoshihiko Hangai*, Hironao Mitsugi* and Kenji Amagai*

* Faculty of Science and Technology, Gunma University

[Published in Journal of the Japan Institute of Metals and Materials, Vol. 86 (2022), pp. 30–33]

https://www.jstage.jst.go.jp/article/jinstmet/86/2/86_J2021046/_article/-char/en

E-mail: t201b017[at]gunma-u.ac.jp

Key Words: porous aluminum, light heating, press working, joining, foam

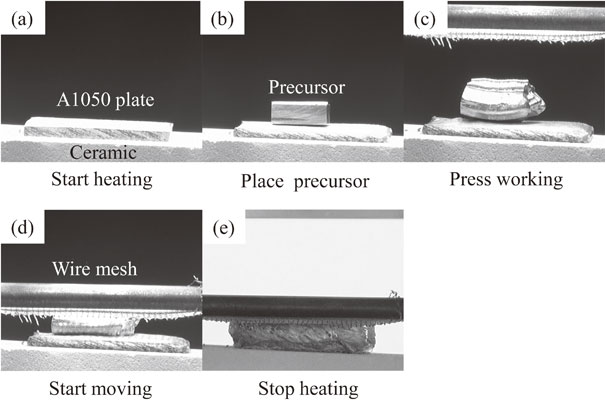

In this study, porous ADC12 (Al-Si-Cu alloy) and an A1050 (commercially pure aluminum) dense plate were joined by press working during foaming. The A1050 dense plate was first heated using an optical heating device, and then the ADC12 precursor was placed on the A1050 dense plate. Next, we attempted to join porous ADC12, and the A1050 dense plate by press working during the foaming of porous ADC12. It was shown that porous ADC12 and the A1050 dense plate can be joined by press working during foaming while maintaining the pore shape of porous ADC12. The joined samples exhibited joining strengths higher than the tensile strength of the porous ADC12 itself.

Photographs of light heating and press working processes.