Metallurgical Abstracts on Light Metals and Alloys vol.56

Joining of two foamed porous aluminum by roll forming immediately after foaming

Kodai Suzuki*, Yoshihiko Hangai* and Kenji Amagai*

* Faculty of Science and Technology, Gunma University

[Published in Journal of The Japan Institute of Light Metals, Vol. 73 (2023), pp. 31–35]

https://www.jstage.jst.go.jp/article/jilm/73/1/73_730106/_article/-char/en

E-mail: t170b057[at]gunma-u.ac.jp

Key Words: foam, jointing, roll forming, friction stir welding

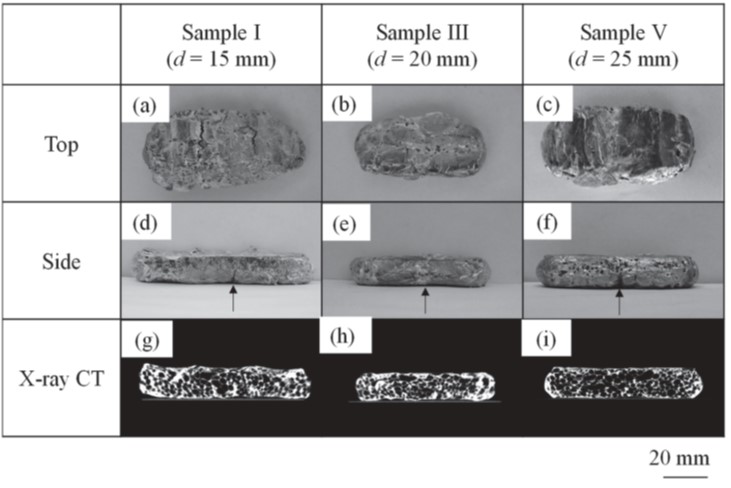

In this study, the joining of porous aluminum by roll forming was attempted. Two precursors were foamed by heat treatment, and the softened porous aluminum immediately after foaming was roll-formed. It was shown that porous aluminum was simultaneously formed and joined by roll forming while maintaining the porous structure of porous aluminum. In the results of the four-point bending test of the joined samples, pores were observed at the fracture surfaces, indicating that strong joining can be achieved by roll forming. In addition, it was found that strong joining was achieved by optimizing the width of the guide rails during roll forming, in accordance with the size of the precursors.

Obtained Sample Ⅰ, Ⅲ, and Ⅴ: (a)- (c) top appearance, (d)- (f) side appearance, and (g)- (i) cross-sectional X-ray CT images.