Metallurgical Abstracts on Light Metals and Alloys vol.56

Creep Behavior of Ti-6Al-4Nb-4Zr Fabricated by Powder Bed Fusion Using a Laser Beam

Yoko Yamabe-Mitarai1, Takashi Inoue2, Tomoki Kuroda1, Sae Matsunaga1, Yoshiaki Toda3, Tetsuya Matsunaga1, Tsutomu Ito4, Ryosuke Ozasa5,

Takuya Ishimoto5, 6 and Takayoshi Nakano5

1 Department of Advanced Materials Science, Graduate School of Frontier Sciences, The University of Tokyo, Kashiwanoha 5-1-5, Kashiwa, Chiba, 277-8561

2 Department of Materials Engineering, The University of Tokyo, Hongo 7-3-1, Bunkyo, Tokyo, 113-8565

3 Research Center for Structural Materials, National Institute for Materials Science, Sengen 1-2-1, Tsukuba, Iabaraki, 305-0047, Japan

4 Department of Mechanical systems Engineering, Faculty of Engineering, Toyama Prefectural University, Kurokawa 5180, Imizu, Toyama, 939-0398, Japan

5 Division of Materials and Manufacturing Science, Graduate School of Engineering, Osaka University, 2-1, Yamada-Oka, Suita, Osaka 565-0871, Japan

6 Aluminium Research Center, University of Toyama, Gohuku 3190, Toyama, Toyama, 930-8555, Japan

[Published in Mater. Trans., Vol. 64, No. 6 (2023), pp.1175-1182]

https://doi.org/10.2320/matertrans.MT-ME2022010

E-mail: Mitarai.yoko[at]edu.k.u-tokyo.ac.jp

Key Words: selective laser melting, heat-resistant Ti alloys, heat treatment, creep, deformation mechanism

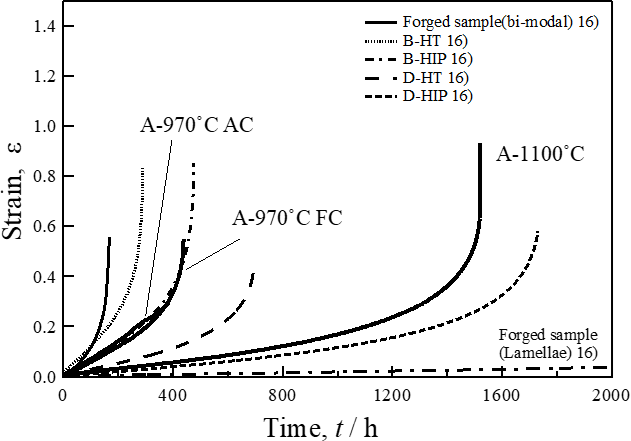

Powder bed fusion using a laser beam (PBF-LB) was performed for Ti-6Al-4Nb-4Zr (wt%) developed by our group to improve the oxidation resistance at temperatures greater than 600 ℃ by adding Nb and Zr to near-α alloys. Microstructure evolution of the PBF-LB samples by heat treatment was investigated, especially for heat treatment duration in the α + β phase, cooling rate, and heat treatment in the β phase. The equiaxed α phase formed during heat treatment along the melting-pool boundaries. The high volume fraction of the α phase and high Nb contents in the β phase was obtained by slow cooling (furnace cooling) compared with fast cooling (air cooling). The α/β lamellar structure formed in the melting pool boundaries with 100 µm in size and no equiaxed α phase formed along the boundaries by heat treatment in the β phase regime. Creep life at 600 ℃ and 137 MPa was similar for the air-cooled and furnace- cooled samples, but the slightly slower deformation was obtained in the furnace-cooled sample. Creep life of the sample in the β phase region drastically increased due to the absence of the equiaxed α phase. Dominant deformation mechanism of creep was grain boundary sliding. The small equiaxed α phase accelerated grain boundary sliding.

Creep curves were recorded at 600 ℃ and 137 MPa for the PBF-LB and forged samples together with the previous study. The creep strain was smaller in the furnace-cooled sample with large volume fraction of the α phase and high Nb contents in β phase, but the effect of the lamellar spacing was small. Heat treatment at 1100 ℃ in β phase effectively improved creep life.