Metallurgical Abstracts on Light Metals and Alloys vol.56

Deformation-restricted forging of Mg-8Al alloy under high pressure

Hiromi Miura, P.L. Khoo and Masakazu Kobayashi

Department of Mechanical Engineering, Toyohashi University of Technology

[Published in Scripta Mater., Vol. 224 (2023), pp.115113]

https://doi.org/10.1016/j.scriptamat.2022.115113

E-mail: miura[at]me.tut.ac.jp

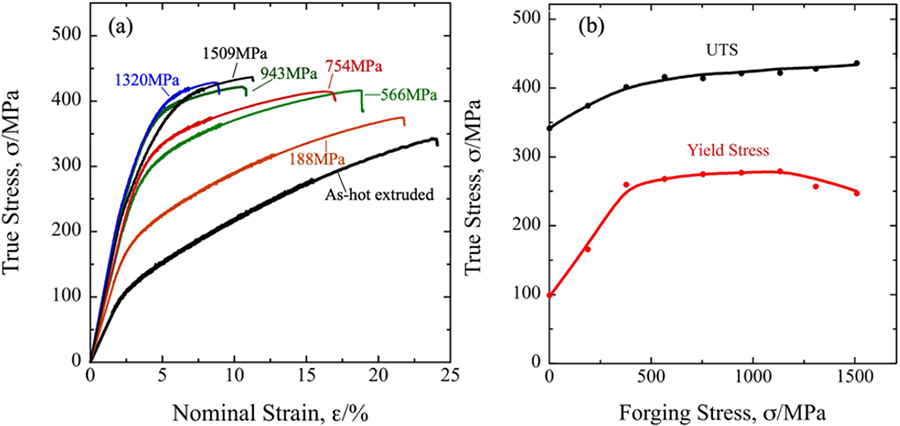

Key Words: Mg alloy, rod, DRF, strength, twin

A new process of deformation-restricted forging (DRF) applicable to the production of long rods is proposed. Magnesium AZ80 alloy disks were forged under conditions of extremely high pressures beyond their fracture strength in a die which eliminated plastic deformation. With increasing forging stress, mechanical twins were formed more frequently which subdivided the coarse initial grains, and the evolved (0001) basal texture became sharper. The mechanical properties tended to be notably improved with increasing forging stress; their modifications were rapid in the forging stress region just under 400 MPa, but became gradual above 400 MPa. The achieved Vickers hardness, yield stress, and ultimate tensile strength were 950 MPa, 280 MPa, and 436 MPa at best, respectively. The improvement of mechanical properties was reasonably understood from grain refinement due to dense mechanical twinning and texture strengthening, as well as strain hardening.

Results of tensile tests of the samples DRFed at various forging stresses. The ultimate tensile strength (UTS) tended to increase with increasing forging stress. UTS over 400 MPa can be achieved.