Metallurgical Abstracts on Light Metals and Alloys vol.56

Effects of Strain Rate on Stress-Strain Curves in 2024 Aluminum Alloy After Solution Heat Treatment

Masahiro Nishida*, Satoshi Taniguchi**, Ziyi Su*, Masaki Sunda* and Masanobu Murata***

* Department of Electrical and Mechanical Engineering, Nagoya Institute of Technology

** System Technology Department, Nagoya Municipal Industrial Research Institute

*** General Support Office, Nagoya Municipal Industrial Research Institute

[Published in Materials Transactions, Vol. 64, No. 2 (2023) pp. 506-513]

https://doi.org/10.2320/matertrans.MT-LA2022020

E-mail: nishida.masahiro[at]nitech.ac.jp

Key Words: Effect of strain rate, Stress triaxiality, Aluminum alloy 2024

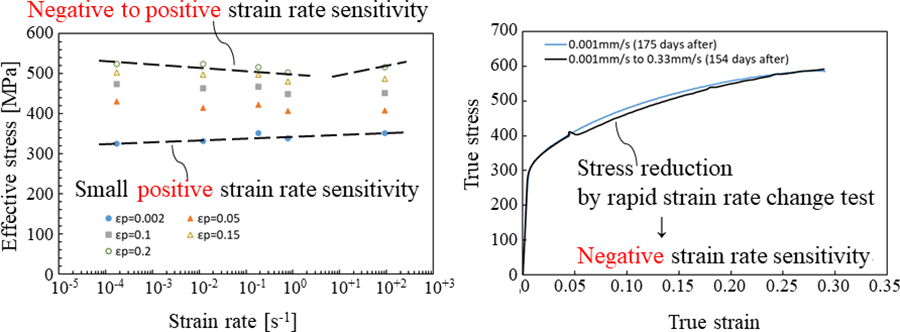

Effects of strain rate on flow stress was examined with respect to aluminum alloy 2024. Stress-strain curves were measured using notched round bar tensile test specimens. Flow stresses of aluminum alloy 2024 were discussed after correcting by an optimization method using both of experimental and simulation results. In the optimization, the experimental results and finite element method simulation results of tensile force-true strain were compared as target curves. After stress correction, the flow stresses at 0.2% strain showed a small positive strain rate sensitivity. The flow stresses at 15% and 20% strain reduced with increasing strain rate in a low strain rate region and increased in a high strain rate region. Fracture strain of aluminum alloy 2024 reduced with increasing strain rate and increased in a high strain rate region.

Negative to positive strain rate sensitivity of aluminum alloy 2024 plate was confirmed just after solution heat treatment. Parameters of material model were determined.