Metallurgical Abstracts on Light Metals and Alloys vol.56

Microstructural factors governing the significant strengthening of Al/Al2Cu mille-feuille structured alloys accompanied by kink-band formation

Koji Hagiharaa,b, Toko Tokunagaa, Shuhei Ohsawaa, Shohei Uemichib, Kai Guanc, Daisuke Egusad and Eiji Abed

a Department of Physical Science and Engineering, Nagoya Institute of Technology, Gokiso, Nagoya, Aichi 466-8555, Japan

b Division of Materials and Manufacturing Science, Graduate School of Engineering,

Osaka University, 2-1, Yamadaoka, Suita, Osaka 565-0871, Japan

c School of Materials Science and Engineering, Jilin University, Jilin, Changchun, 130025, China

d Department of Materials Science & Engineering, University of Tokyo, Tokyo 113-8656, Japan

[Published in International Journal of Plasticity, Vol. 158 (2022), pp.103419]

https://doi.org/10.1016/j.ijplas.2022.103419

E-mail: Hagihara[at]nitech.ac.jp

Key Words: Deformation kink band, Aluminum alloy, Plastic deformation, Mille-feuille structure, Mechanical properties

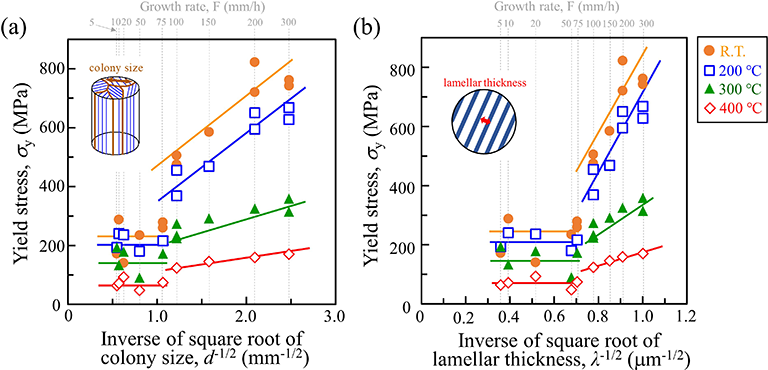

Development of high-strength Al alloys that can be used at temperatures above 150 ℃ is strongly desired. To achieve this, Al/Al2Cu mille-feuille structured alloys, in which soft (Al) layer and hard (Al2Cu) layer are alternatively stacked in lamellar form, is recently focused, via inducing kink-band formation as a novel strategy for controlling the mechanical properties. There was little information to derive a "general law" for quantitatively predicting an increase in yield stress in mille-feuille structured alloys from a microstructure perspective. In this study, we successfully distinguished the effects of lamellar thickness and colony size on the strength. The results demonstrated that the yield stress governed by kink-band formation is irrelevant to the lamellar thickness in the Al/Al2Cu alloys but it depends on the colony size. The decrease in lamellar colony size obtained by increasing the growth rate during the directional solidification of the Al/Al2Cu eutectic alloy can induce the homogeneous formation of tiny kink bands in the alloy, leading to a drastic increment of the yield stress accompanied by ductility. The control of the morphology of kink band changes its role from a fracture mode to a deformation mode. Furthermore, such microstructure control can induce “kink-band strengthening” in the alloys.

Relation between the yield stress and the inverse of the square root of (a) lamellar thickness and (b) colony diameter in directionally solidified Al/Al2Cu mille-feuille structured crystals.