Metallurgical Abstracts on Light Metals and Alloys vol.56

Effect of Surface Treatment on Hydrogen Embrittlement of 6061-T6 Aluminum Alloy

Makoto Hino*, Kota Kawaue*, Ryoichi Kuwano*, Koji Monden**, Masaaki Sato**, Yukinori Oda**, Keitaro Horikawa*** and Teruto Kanadani****

* Department of Mechanical System, Graduate School of Engineering, Hiroshima Institute of Technology

** C.Uyemura & Co., Ltd

*** Graduate School of Engineering Science, Osaka University

**** Professor emeritus, Okayama University of Science

[Published in J. Surf. Finish. Soc., Vol. 73 (2022), pp.646-648]

https://www.jstage.jst.go.jp/article/sfj/73/12/73_646/_article/-char/en

E-mail: hino[at]me.it-hiroshima.ac.jp

Key Words: 6061-T6 aluminum alloy, hydrogen embrittlement, electroless Ni-P plating, fatigue test

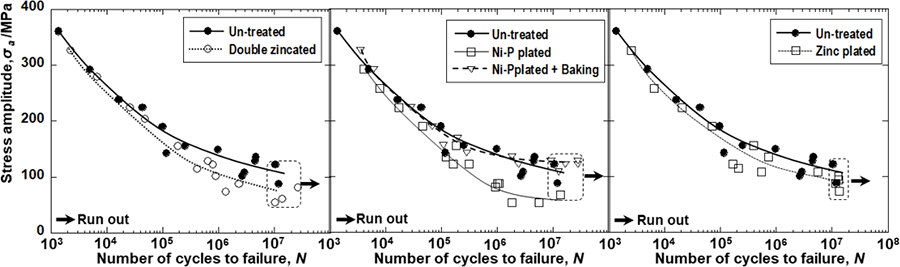

Effects of various surface treatments on hydrogen embrittlement of 6061-T6 aluminum alloy were investigated. Rotary bending fatigue tests showed that electroless Ni-P plating on 6061-T6 reduced the fatigue strength considerably because of hydrogen absorbed into the substrate by plating. These findings suggest the possibility of evaluating hydrogen embrittlement of 6061-T6 by conducting rotary bending fatigue tests after electroless Ni-P plating.

Relation between stress amplitude (σ a) and number of cycles to failure (N) for the un-treated and various surface treated specimens.