Metallurgical Abstracts on Light Metals and Alloys vol.56

Evaluation of hydrogen embrittlement of three aluminum alloys by three-point bending test affected by three types of plating

Kota Kawaue*, Makoto Hino*, Ryoichi Kuwano*, Yukinori Oda**, Keitaro Horikawa*** and Teruto Kanadani****

* Mechanical Systems Engineering, Graduate School of Engineering, Hiroshima Institute of Technology

** C.Uyemura & Co., Ltd

*** Graduate School of Engineering Science, Osaka University

**** Professor emeritus, Okayama University of Science

[Published in Journal of The Japan Institute of Light Metals, Vol. 73 (2023), pp.196-200]

https://www.jstage.jst.go.jp/article/jilm/73/5/73_73_730502/_article/-char/en

E-mail: hino[at]me.it-hiroshima.ac.jp

Key Words: aluminum alloy; hydrogen embrittlement; plating; three-point bending test; thermal desorption analysis

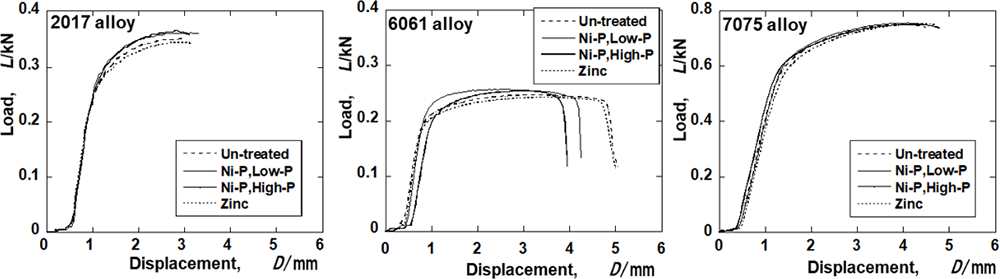

Hydrogen embrittlement affected by three types of plating (low-P and high-P types electroless Ni-P plating and electrolytic Zn-platin) was investigated by means of slow-strain-rate three-point bending test on three aluminum alloys (2017-T3, 6061-T6 and 7075-T651). Hydrogen generated by the Ni-P and zinc plating was absorbed by the aluminum alloy substrates, and the trap sites in the aluminum alloy substrates for the absorbed hydrogen differed between Ni-P and zinc plating. Hydrogen embrittlement was able to be evaluated by the three-point bending tests on plated aluminum alloys. Zinc plating did not cause embrittlement for all the alloys, but Ni-P plating induced embrittlement only for the 6061-T6 aluminum alloy. The result of embrittlement of the Ni-P plated 6061-T6 aluminum alloy corresponds to the highest amount of hydrogen desorbed below 240°C than the other alloys.

Fig. 5 Load-displacement curves of the three alloy substrates un-treated and plated in the three ways, subjected to the three-point bending test.