Metallurgical Abstracts on Light Metals and Alloys vol.56

Microstructure and Mechanical Properties of Al2O3-Particle-Reinforced Al-Matrix Composite Sheets Produced by Accumulative Roll Bonding (ARB)

Wenchuang Liu*, Yujiao Ke**, Kenjiro Sugio*, Xingang Liu**, Ying Guo* and Gen Sasaki*

*Graduate School of Advanced Science and Engineering, Hiroshima University

**College of Mechanical Engineering, Yanshan University

[Published in Materials Science & Engineering A 850 (2022) 143574]

https://doi.org/10.1016/j.msea.2022.143574

E-mail: gen[at]hiroshima-u.ac.jp

Key Words: Aluminum matrix composites (AMCs), Accumulative roll bonding (ARB), Microstructure, Machine learning, Particle spatial distribution

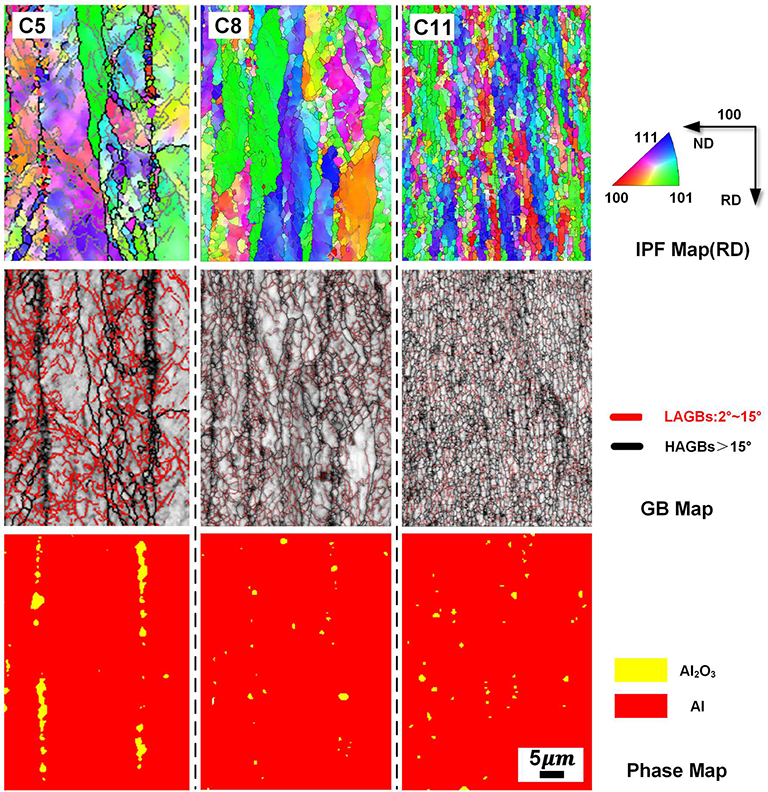

Accumulative roll bonding (ARB) was used to fabricate aluminum matrix composites (AMCs) with 2 vol% Al2O3 particles. Monolithic sheets without Al2O3 particles under the same conditions were also fabricated for comparison. For all produced sheets, different variables, such as average grain size, fraction of high angle grain boundaries and local number of 2-dimension at random points (LN2DR), were measured to better understand the evolution of matrix microstructure and particle spatial distribution. The role of Al2O3 particles on strengthening in AMCs processed by ARB was finally revealed. It was found that during ARB, monolithic sheets exhibited deformed-micrometer grains. In comparison, composites also started with deformed-micrometer grains, however, evolved over ARB cycles to have significantly refined grains. Machine learning results showed that particle spatial uniformity improved with the increasing number of ARB cycles. After the 11 cycles of ARB, final composites were more strengthened (1.15 times higher Vickers hardness, 1.19 times higher tensile strength), however, had less elongation than the monolithic sheets. Therefore, comparing to monolithic sheets, the composites are more strengthened not only due to the matrix strain hardening and grain refinement caused by ARB, but also the presence of Al2O3 particles with improved spatial uniformity.

Inverse pole figure (IPF) maps of RD, grain boundary (GB) maps, and phase maps of the RD-ND planes (center) of the composite samples processed by 5, 8 and 11 ARB cycles.