Metallurgical Abstracts on Light Metals and Alloys vol.56

Development of High-Strength Al-Cu-Mg Alloy by Combined Application of High-Pressure Torsion and Aging Treatment

Pengcheng Ma*, Takahiro Masuda*,**, Shoichi Hirosawa* and Zenji Horita***,****,*****

*Department of Mechanical Engineering and Materials Science, Yokohama National University

**Division of Materials and Manufacturing Science, Graduate School of Engineering, Osaka University

***Graduate School of Engineering, Kyushu Institute of Technology

****Magnesium Research Center, Kumamoto University

*****Synchrotron Light Application Center, Saga University

[Published in Materials Transactions, Vol. 64 (2023), pp.514-521]

https://doi.org/10.2320/matertrans.MT-LA2022049

E-mail: hirosawa[at]ynu.ac.jp

Key Words: High-pressure torsion (HPT), Grain refinement, Aluminum alloy, Aging treatment

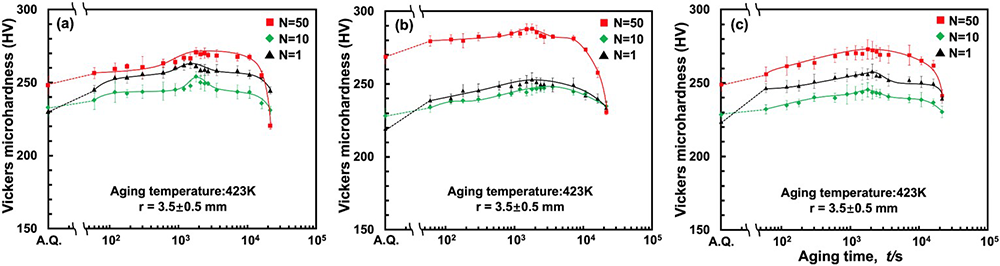

Solution treated AlCuMg alloys with three different compositions were subjected to high-pressure torsion (HPT) for 1 to 50 turns, and then aged at 423 K. By conducting HPT process, the hardness of the three alloys significantly increased after 50 turns, and the average grain sizes were refined to 130-140 nm. After aging treatment, the hardness was further increased to 271HV, 288HV and 273HV in the peak aging condition for the Al4Cu1.5Mg, Al4Cu3Mg and Al5Cu3Mg (in mass%) alloys, respectively. The contribution of several strengthening mechanisms was quantitatively evaluated in terms of grain boundary hardening, dislocation hardening, solid solution hardening and cluster/precipitation hardening. It is shown from the quantitative evaluation that simultaneous strengthening due to grain refinement and nanoscale precipitates is successfully achieved by combined application of HPT process and subsequent aging treatment.

Hardness variation of the HPT-processed samples of (a) Al4Cu1.5Mg, (b) Al4Cu3Mg and (c) Al5Cu3Mg alloys during aging at 423 K.