Metallurgical Abstracts on Light Metals and Alloys vol.56

Influence of Input Energy Density on Morphology of Unique Layered Microstructure of γ-TiAl Alloys Fabricated by Electron Beam Powder Bed Fusion

Ken Cho*, Naohide Morita*, Hiromasa Matsuoka*, Hiroyuki Y. Yasuda*, Mitsuharu Todai**, Minoru Ueda***, Masao Takeyama**** and Takayoshi Nakano*

*Graduate School of Engineering, Osaka University

**Department of Environmental Materials Engineering, Institute of Niihama National College of Technology

***Metal Technology Co. Ltd.

****Department of Metallurgy and Ceramics Science, Tokyo Institute of Technology

[Published in Materials Transactions, Vol.64 (2023), pp.44-49]

https://doi.org/10.2320/matertrans.MT-MLA2022015

E-mail: k_cho[at]mat.eng.osaka-u.ac.jp

Key Words: Additive manufacturing, Titanium aluminide, Microstructure, Tensile properties

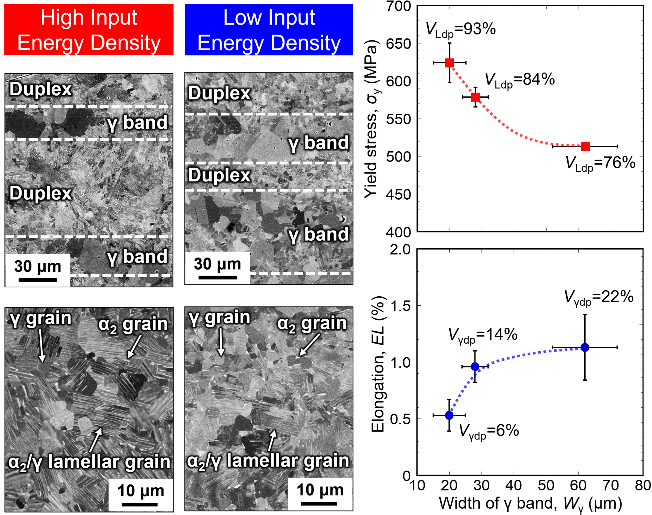

Microstructure and mechanical properties of Ti-48Al-2Cr-2Nb (at%) rods prepared by electron beam powder bed fusion (EB-PBF) process were investigated by changing input energy density (ED). We found that a unique layered microstructure consisting of a duplex region and an equiaxed γ grain layer (γ band) can be formed by the process with ED in the range of 13 to 31 J/mm3. Not only the volume fraction of the γ phase in the duplex region but also the width of the γ band decrease with increasing ED. Whereas, the α2/γ lamellar grain in the duplex region increases with increasing ED. These changes in the morphology of the layered microstructure are attributed to the change in temperature distribution from the melt pool due to increased ED. In addition, we also found for the first time the strength of the alloys with the layered microstructure can be improved by increasing of the α2/γ lamellae in the duplex region and decreasing width of the γ band. In contrast, to increase the ductility of the alloy, the fraction of the equiaxed γ grain in the duplex region and the width of the γ band must be increased.

Microstructure of the rods fabricated at high and low input energy density (a) and variations in the yield stress and elongation at room temperature of the rods as a function of the width of the γ band.