Metallurgical Abstracts on Light Metals and Alloys vol.56

Microstructure and Shape Evolution in Ti-10V-2Fe-3Al Alloy by Tempering

Yoshito Takemoto

Graduate School of Natural Science and Technology, Okayama University

[Published in TITANIUM JAPAN, Vol. 71, (2023), pp.204-207]

E-mail: takemoto[at]mech.okayama-u.ac.jp

Key Words: α"-martensite distribution, Shape memory , Shape revolution, Reverse transformation

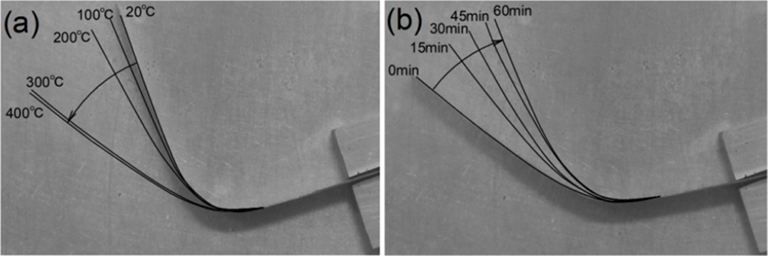

Solution-treated (STQ) materials of Ti-10Mo-7Al or Ti-15V-7Al alloys are known to have a β+α"Mq microstructure and to exhibit peculiar phenomena during tempering. Commercially available Ti-10V-2Fe-3Al (Ti-1023) alloy STQ-treated materials are also known to have a similar β+α"Mq structure. Therefore, the peculiar phenomenon associated with tempering of Ti-1023 alloy was investigated. The microstructure of STQ-treated Ti-1023 was found to change to β single phase after tempering at 300℃ for 3 min, and almost complete α"Mt was reversibly generated after treatment at 550℃ for 5 sec. Cross-sectional observation revealed that α"Mq in the STQ material tended to form in the interior of the specimen, while α"Mt from tempering at 550℃ tended to form in the surface layer of the specimen. When a thin plate of STQ material was bent into a U-shape and heated, shape recovery was observed as in the case of Ti-10Mo-7Al, followed by shape evolution. Therefore, a peculiar phenomenon due to tempering also appears in Ti-1023, but the β reverse transformation temperature and α"Mt transformation temperature are about 100℃ higher than those of Ti-10Mo-7Al, respectively. Phase decomposition associated with aging at 450℃ follows the process β + α"Mq → β + α"Mt → β → β + α, but no formation of α"iso was observed.

(a) Shape change of U-bent specimen of Ti-10V-2Fe-3Al alloy during temperature increase to 400℃.

(b) Shape change of U-bend specimen during holding at 420℃ for 1 hour after the temperature rise in (a).