Metallurgical Abstracts on Light Metals and Alloys vol.56

Effect of a Heterogeneous Nitrogen Diffusion Phase on Four-point Bending Fatigue Properties in Commercially Pure Titanium

Shoichi Kikuchi*, Shiori Suzuki**, Hideaki Ito**, Keisuke Fujita*** and Kenta Nakazawa*

* Faculty of Engineering, Shizuoka University

** Graduate School of Integrated Science and Technology, Shizuoka University

*** Graduate School of Science and Technology, Shizuoka University

[Published in Materials Transactions, Vol. 63 (2022), pp.1046-1054]

https://doi.org/10.2320/matertrans.MT-Z2022004

E-mail: kikuchi.shoichi[at]shizuoka.ac.jp

Key Words: Fatigue, Gas nitriding, Commercially pure titanium

The purpose of this study is to develop commercially pure (CP) titanium having a higher fatigue strength than titanium alloys developed via heterogeneous nitrogen diffusion. The microstructure of CP titanium having a heterogeneous nitrogen diffusion phase, which was fabricated by consolidating gas-nitrided powders, was characterized, and its fatigue properties were examined. The nitrogen content and hardness of CP titanium compacts having a heterogeneous nitrogen diffusion phase increased with increasing powder gas nitriding temperature and sintering temperature. The fatigue limit and fatigue life of CP titanium compacts increased with increasing sintering temperature and with decreasing powder gas-nitriding temperature. In particular, CP titanium having a heterogeneous nitrogen diffusion phase that is fabricated by high-temperature sintering of powders treated with low-temperature nitriding has a higher fatigue limit than un-nitrided bulk Ti-6Al-4V alloy. The fatigue limit of CP titanium can be controlled by optimizing the powder gas nitriding and sintering temperatures.

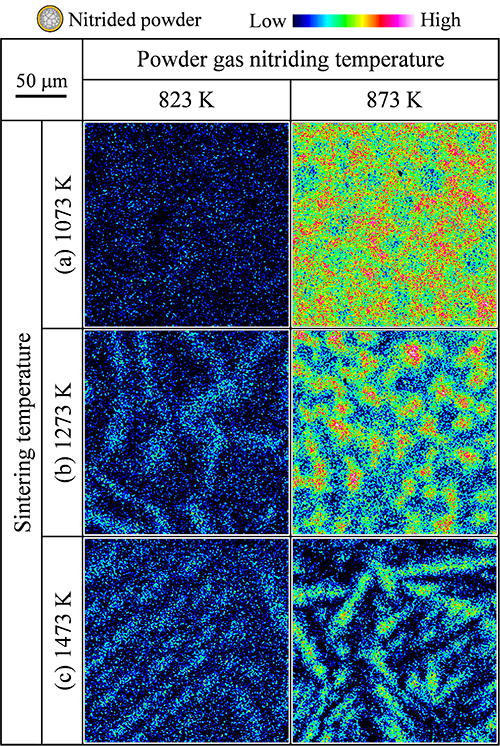

Nitrogen maps for sintered compacts fabricated from gas-nitrided powders, as measured by EPMA.