Metallurgical Abstracts on Light Metals and Alloys vol.56

Effect of multifunction cavitation treatment on the surface of thin plates of Al alloys

Masataka Ijiri*, Takayuki Ogi** and Toshihiko Yoshimura**

* Department of Mechanical Systems Engineering Faculty of Systems Design, Tokyo Metropolitan University

** Department of Mechanical Engineering Faculty of Engineering, Sanyo-Onoda City University

[Published in Results in Materials, Vol. 16 (2022), 100329]

https://doi.org/10.1016/j.rinma.2022.100329

E-mail: ijiri[at]tmu.ac.jp

Key Words: Multifunction cavitation, Thin plate, Pure Al, Al alloy, Tensile strength

The high strength of a thin plate surface produced by peening treatment is not yet used in industrial products, even when the mechanical properties are improved, due to warpage after the surface treatment. In this study, we focused on multifunction cavitation technology (MFC), which improves various properties while suppressing surface roughness compared with conventional peening treatment. Thin plate samples of four aluminum alloys, A1050, A2017, A5052, and A6061, were used, and the surface of samples 1 mm thick was treated with MFC. The surface roughness increased slightly for each sample, and the hardness and compressive residual stress increased except for A1050. The amount of warpage was reduced in A6061, which is the hardest aluminum alloy used in this study. Furthermore, the tensile strength of the MFC-treated sample decreased in A2017, but increased in A5052 and A6061. These results showed that MFC-treated A5052 and A6061 are most likely to be strengthened.

Figure 1 shows the surface roughness for each aluminum material after MFC treatment. The surface roughness increased in the order A1050 (A_1), A5052 (A_3), A2017 (A_2), and A6061 (A_4). The amount of change is considered to depend on the hardness of the surface.

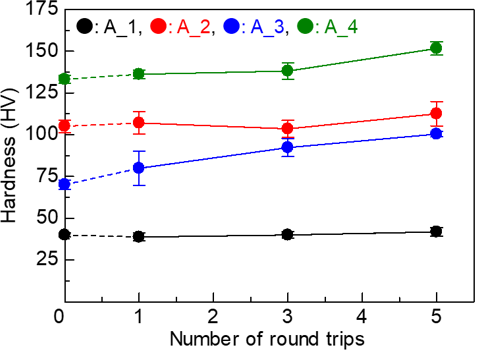

Figure 2 shows the hardness of each Al alloy after MFC treatment. The magnitude of the initial hardness was different for each alloy. The surface of alloys A_1 and A_2 almost did not change before and after the treatment, but it was found that the hardness of A_3 and A_4 increased after the treatment.

The hardness of A_1 did not change compared to the initial hardness because no element was present to increase the hardness. Because A_2 was strengthened by natural aging, the surface temperature during MFC processing increased compared to the temperature of natural aging, so it is considered that dislocations due to the increase in hardness are unlikely to remain. Because A_3 and A_4 were subjected to an aging treatment temperature higher than that for A_2, it is considered that the hardness of the MFC-treated sample increased due to the further increase in precipitates and the accumulation of dislocations. The increase in hardness of the MFC-treated surface is likely to be enhanced for Al alloys that are subjected to artificial aging temperatures higher than the natural aging temperature.

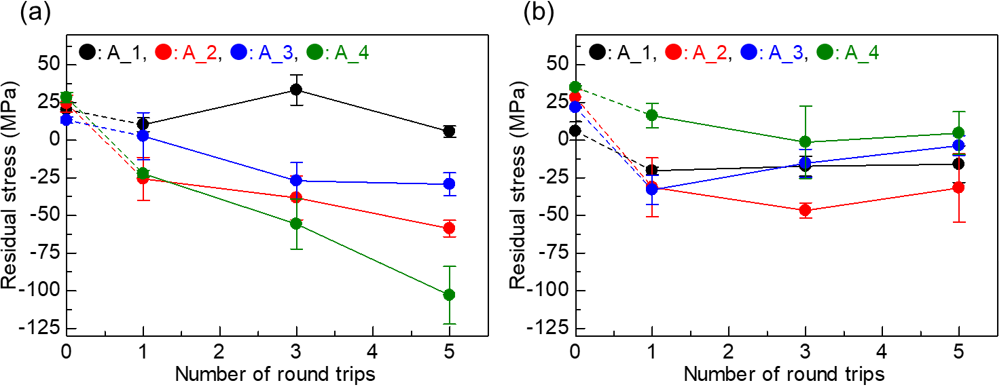

To confirm the fatigue characteristics of the MFC-processed samples, Fig. 3 shows the residual stress for their (a) front surface and (b) back surface. These samples were processed only on the surface. In Figure 9(a), the residual stress for alloy A_1 was almost unchanged compared with the untreated surface, and compressive residual stress was not applied to the surface after processing. For A_2, A_3, and A_4, the initial tensile residual stress was converted to compressive residual stress following treatment. In addition, as shown in panel (b), compressive residual stress was generated in A_1, A_2, and A_3, and tensile residual stress was present in A_4, which was the same as in the untreated material. This is because the balance of residual stress on the front and back surfaces is considered to be the cause of warpage.

Fig. 1 Surface roughness of samples processed using MFC as function of number of round trips.

Fig. 2 Hardness of samples processed using MFC as function of number of round trips.

Fig. 3 Residual stress for various alloy samples processed using MFC as function of number of round trips. (a) Front surface and (b) back surface.