Metallurgical Abstracts on Light Metals and Alloys vol.56

Effect of polyethylene glycol modification on the corrosion behaviour of hydroxyapatite-coated AZ31 Mg alloy under tensile deformation

Sachiko Hiromoto* and Kotaro Doi*

* Research Center for Structural Materials, National Institute for Materials Science

[Published in Corrosion Science, Vol. 212 (2023), 110931]

https://doi.org/10.1016/j.corsci.2022.110931

E-mail: hiromoto.sachiko[at]nims.go.jp

Key Words: calcium phosphate, polymer, composite coating, slow strain rate tensile test, rapid strain electrode test, stress corrosion cracking

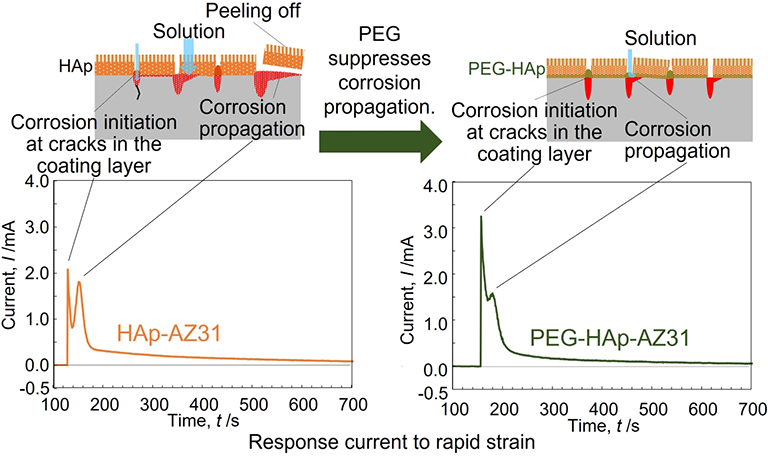

The effect of polyethylene glycol (PEG) modification on the corrosion behaviour under tensile deformation of hydroxyapatite-coated Mg-3mass% Al-1mass% Zn (HAp-AZ31) was examined in Hanks’ solution. Slow strain rate tensile (SSRT) and rapid straining electrode (RSE) tests and electrochemical impedance measurements were performed. In SSRT tests, PEG-modified HAp-AZ31 showed 1.4 times longer elongation to failure than HAp-AZ31. In RSE tests, the response current curves to the rapid strain showed two peaks corresponding to crack initiation in the coating layer and corrosion propagation. From the changes in these peak currents, it was found that the PEG modification showed little effect on cracking of HAp coating, while it reduced corrosion propagation from the cracks by half. PEG was preferentially present at the interface between HAp coating layer and substrate, which presumably increase the adhesive strength of the coating layer. The improvement in tensile elongation of HAp-AZ31 with PEG is attributed to the inhibition of corrosion propagation from coating cracks.

Corrosion initiates at crack sites in the HAp and PEG-HAp coating layer propagates as the coating is peeled off. The PEG modification inhibits the corrosion propagation.