Metallurgical Abstracts on Light Metals and Alloys vol.56

Improving the Corrosion Resistance of TNTZ in Hank’s Solution after Thermomechanical Treatment

Sir Anderson*, Jon Affi*, Yuli Yetri**, Mitsuo Niinomi***, Toshikazu Akahori**** and Gunawarman*

* Department of Mechanical Engineering, Universitas Andalas

** Department of Mechanical Engineering, Politeknik Negeri Padang

*** Institute for Materials Research, Tohoku University

**** Department of Material Science and Engineering, Meijo University

[Published in Journal of Hunan University (Natural Sciences), Vol. 49, No. 11, (2022), 96-109]

https://doi.org/10.55463/issn.1674-2974.49.11.12

E-mail: akahori[at]meijo-u.ac.jp

Key Words: titanium alloy, TNTZ, corrosion, thermomechanical treatment, plastic deformation

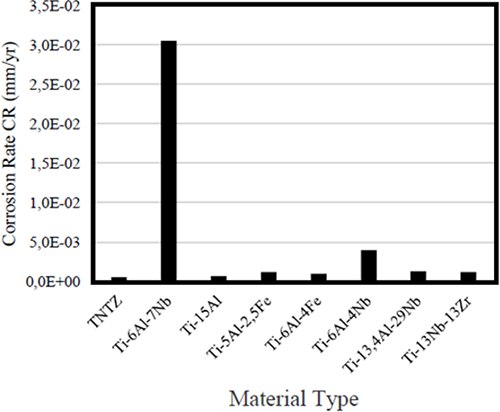

Ti-29Nb-13Ta-4.6Zr (TNTZ) is a new titanium alloy potentially to be used as bone implant material because of its advantages in terms of strength, ductility, non-toxicity, corrosion resistance, and biocompatibility. Although its mechanical properties are suitable for bone applications, there are still problems related to its corrosion behavior when used for a long time. Therefore, this research aims to determine the corrosion rate and type and provide corrosion prevention by applying the thermomechanical treatment on TNTZ in Hank’s solution. The thermomechanical treatment was proved to reduce the pitting corrosion in TNTZ. The results showed that thermomechanical treatment with increased plastic deformation reduce the value of the corrosion rates. TNTZ after thermomechanical treatment had the lowest corrosion rate, while Ti-6Al-7Nb had the highest one.

Comparison of corrosion rates of various alpha/beta and beta type- titanium alloys in Hank’s solution.