Metallurgical Abstracts on Light Metals and Alloys vol.56

Bonding of Magnesium Alloy with Ceramics by Shot Peening

Yasunori Harada* and Kenta Sugihara**

* Graduate School of Engineering, University of Hyogo

** Graduate Student, University of Hyogo

[Published in Proceedings of ICSP14, Doc ID 2022084 (2022)]

https://www.shotpeener.com/library/detail.php?anc=2022084

E-mail: harada[at]eng.u-hyogo.ac.jp

Key Words: bonding, surface treatment, shot peening, magnesium alloy, wear resistance

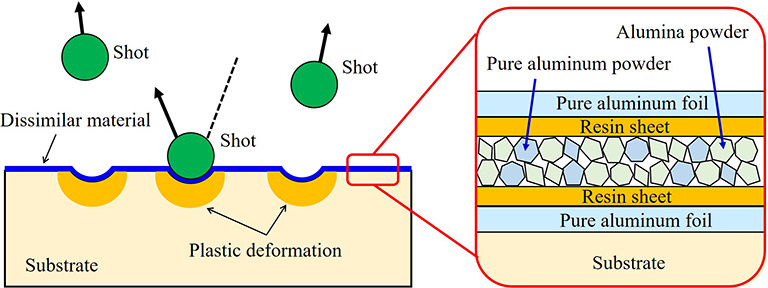

Light metal materials such as aluminum and magnesium alloys are widely used in the field of transportation equipment where weight reduction of mechanical parts is required. However, it is known that wear resistance of light metals is lower than that of steel materials. Therefore, surface modification is being attempted by various coating techniques. In the present study, to improve the surface characteristics of corrosion resistance and wear resistance of light metals, surface modification was performed by bonding laminated sheet with ceramic powders and resin sheet to magnesium alloy using shot peening. The bondability of the laminated sheet was examined. Dissimilar material is a laminated sheet composed of ceramic powders and the resin sheets. Ceramic was a hard alumina with a powder size of 0.06 to 0.3 mm. The structure of the cross section was observed by an optical microscopic observation near the surface where the laminated sheet was bonded. The bondability of dissimilar materials was tested by a three-point bending test.Wear resistance was also evaluated. The laminated sheet could be bonded without peeling from the substrate. Bonding of hard powders was effective in improving wear resistance.

Bonding method of laminated sheet by shot peening. Dissimilar material is a laminated sheet composed of ceramic powders and the resin sheets.