Metallurgical Abstracts on Light Metals and Alloys vol.56

Drawability of Titanium Corrugated Cup Using Roller Ball Die

Yasunori Harada* and Haruki Izumi**

* Graduate School of Engineering, University of Hyogo

** Graduate Student, University of Hyogo

[Published in Proceedings of JSME International Conference on Materials and Processing 2022, (2022)]

E-mail: harada[at]eng.u-hyogo.ac.jp

Key Words: sheet forming, deep drawing, drawability, titanium, clad, corrugated

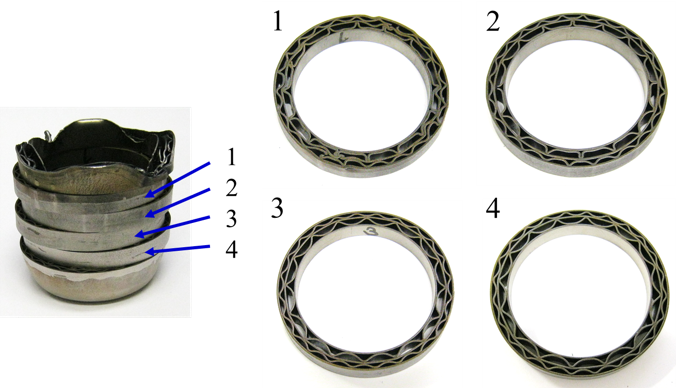

Drawing is a type of press work that uses punches and dies to create a seamless container-shaped product from a flat sheet. This is used not only for containers, but also for industrial products and machine parts because it can be used to process a variety of cylindrical shapes and square cylinders. In the present study, an attempt was made to form pure titanium corrugated cup with a structure similar to a corrugated paper cross-section for the forming of lightweight and high-strength functional cups. The test material was commercially available pure titanium. To form the cup into a corrugated shape, the roller ball die was used. In the roller ball die, the shoulders were grooved, and the steel balls were arranged in the grooves in a ring shape. Three- and five-layer clad cups were formed using the composite die with the structure consisting of alternating roller ball dies and regular dies. The formability of the drawn cups was evaluated by measuring thickness strain and compressive strength. No fracture occurred in the forming of the corrugated cup. The thickness reduction at the bottom of the cup was less than 12 %. It was found to be fully usable as the cup.

Appearances of cutting side wall of five-layer clad cup. There was a gap in the side wall, and a regular wave shape was observed.