1

Pore Formation and Shape Control Simulation of Lotus Aluminum by Phase Field Method

[Published in ACS Omega 2022 7 (17), 14985–14993]

Phase field of the pore obtained in a system with multiple nucleation.

Metallurgical Abstracts on Light Metals and Alloys vol.55

[Published in ACS Omega 2022 7 (17), 14985–14993]

Phase field of the pore obtained in a system with multiple nucleation.

[Published in International Journal of Hydrogen Energy, Vol. 46 (2021), pp. 37502–37508]

[Published in Journal of the European Ceramic Society 42 (2022) 2707–2717]

[Published in Materials Transactions, Vol. 63 (2022), in press]

Variation of start temperature of β→ωi transformation as a function of oxygen concentration in Ti-20 at%Nb alloys. The oxygen addition accelerated and then suppressed the β→ωi transformation.

[Published in Metals, Vol. 12 (2022), Issue 1, 2]

[Published in Advanced Powder Technology, 32 (2021), pp. 2379–2389]

SEM-EDS (a) and XRD results (b) of core-shell structured Ti-N powder, tensile properties of Ti-N alloys fabricated by AM and PM process (c) and their fractured surfaces after tensile test (d).

[Published in Applied Physics Express, Vol. 14 (2021), pp. 062001_1–4]

[Published in ISIJ international, Vol. 61 (2021), pp. 2844–2854]

Comparison of the 0.2% proof stress between the machine learning (neural network) result and experimental result (Ti-17 alloy with various kinds of microstructures).

[Published in Materials Science & Engineering A, Vol. 815 (2021), 141221]

Fatigue behavior and dislocation structure of pure Al strongly depend on the activity of cross slip.

[Published in Philosophical Magazine, Vol. 102(1) (2022), 60–68]

Fatigue-induced dislocation structure in pure Al can be easily rearranged by the activity of cross slip.

[Published in Journal of Alloys and Compounds Vol. 889 (2021), 161815]

TEM high-resolution lattice images and diffractograms of (a) Al, Al3Ti, and AlTi3, and (b) AlTi and ω-Ti in sample processed by HPT for 100 revolutions.

[Published in J. Appl. Phys. Vol. 131 (2022), 105903]

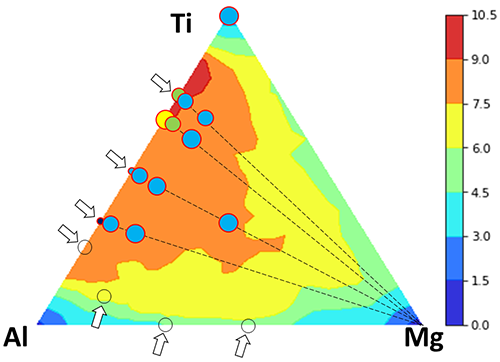

Mapping of Tc in an Al-Ti-Mg triangle, predicted by machine learning. The arrows indicate the compositions corresponding to the stable phases. The red circles represent samples prepared via the HPT processing.

[Published in Materials transactions, Vol. 63, Issue 4 (2022), pp. 586–591]

3D DCT reconstruction of grains in Al-Zn-Mg alloy. Colors according to IPF key shown in the inset.

[Published in Scripta Materialia, Vol. 211 (2022), 114503]

Stress-strain curves of monotonic tensile test on three grain sizes (a) and Bauschinger test on UFG-1 (b), UFG-2 (c) and CG (d) specimen.

[Published in Materials Transactions, Vol. 62, No.8 (2021), pp. 1124–1132]

Stress components of equal plastic work. Solid and open circles represent experimental and simulation results of the dislocation-density-based hardening model.

[Published in Materials Transactions, Vol. 63, No. 1 (2022) pp. 27–32]

(Left) Fatigue S-N plots of Mg-0.026 at% Ce single crystals with different orientations.

(Right) Fatigue crack propagation mechanism of (a) pure magnesium single crystal and (b) Mg-Ce single crystals.

[Published in Materials Transactions, Vol.62(2021), pp. 1502–1509]

Schematic illustration of surface modified layers created and wear behavior of Gas Blow IH nitriding(N series), FPP treated(F series), and GBIH nitride with post-treatment with FPP(N+Fseris) specimens.

[Published in J. Electrochem. Soc., Vol. 168 (2021), 103506]

Our approach offers a new strategy for preparing hard anodic films with low porosity under mild anodization conditions to prevent burning.

[Published in Journal of the Electrochemical Society, Vol. 169 (2022) 021508]

Anticorrosive magnesium hydroxide composite films were prepared on magnesium alloy by steam coating. The corrosion resistance was lowered with an increase in the immersion time.

[Published in Journal of The Japan Institute of Light Metals, Vol. 72, No. 4 (2022), pp. 122–126]

https://www.jstage.jst.go.jp/article/jilm/72/4/72_720402/_article/-char/en

Change in value of true strain measured in radial direction (from major axis of ellipse), circumferential direction (from minor axis of ellipse) and thickness direction at sequentially numbered locations (measurement point) of deep-drawn cup.

[Published in Science and Technology of Advanced Materials, Vol. 23 (2022), pp. 322–331]

Photo current transient, photocurrent responses, calculated photoelectrochemical action spectra, and the resultant electronic band structures of passive films formed on Ti in Hanks and saline.

[Published in Materials Transactions, Vol. 62 (2021), pp. 1771–1776]

Anisotropic compression behavior of ordered open-cell porous titanium.

[Published in ISIJ International, Vol. 62 (2022), pp. 1512–1521]

[Published in Diamond and Related Materials, Vol. 116 (2021), pp. 108432]

A gap can be observed between CF and Al matrix in the uncoated CFs/Al sample, while an interfacial layer can be seen between CF and Al matrix in the Ni-coated CFs/Al sample.

[Published in Journal of Composite Materials, Vol. 56 (2022), pp. 1987–2001]

As the ceramic particle content increased, the yield strength and tensile strength of the AMCs enhanced, while the elongation of those decreased.

[Published in J.JFS, Vol. 93 (2021), pp. 604–611]

https://www.jstage.jst.go.jp/article/jfes/93/10/93_604/_article/-char/en

Effect of particle parameters on maximum hydrostatic stress. It is found that most effective parameter for stress concentration of particle in early stage is particle shape (local neck).

[Published in Journal of Japan Foundry Engineering Society, 92, No. 9, 525–531 (2021)]

https://www.jstage.jst.go.jp/article/jfes/93/9/93_525/_article/-char/en

Effect of baking temperature for plaster mold on relative density of centrifugally cast Al. Plaster molds were fabricated with and without zbond 90 infiltration.

[Published in Journal of Japan Institute of Light Metals, 72, No. 5, 198–205 (2022)]

https://www.jstage.jst.go.jp/article/jilm/72/5/72_7205-T11/_article/-char/en

Relative density, ρ, of the samples with 0vol%, 0.1vol%, 0.5vol% and 1.0vol% TiC heterogeneous nucleation site particles plotted against energy density, E.

[Published in Proceeding of 33rd International Symposium on Space Technology and Science (33rd ISTS), (2022), paper No. 2022–r–21p]

The temperature increasing of 100°C slightly affect crate size and the number of ejecta from aluminum alloy 6-61-T6 at hypervelocity impact. They were slightly decreased by the addition of plastic sheet.

[Published in Materials Science & Engineering A, Vol. 825 (2021), pp. 141849]

SEM-EBSD crystal orientation maps showing the variation in the crystal orientation due to the formation of deformation bands in a mille-feuille structured Al/Al2Cu alloy.

[Published in Scripta Materialia, Vol. 210 (2022), pp. 114480–1–4]

Snapshots of Mg-Y-vacancy systems and averaged coordination numbers of Y atoms in the second-nearest neighbor shell in Mg-3.0 at.%Y alloys obtained from KMC calculations at various temperatures.

[Published in Materialwissenschaft und Werkstofftechnik (Material Science and Engineering Technology), 52 (2021) 339–345]

Fig. 1 Yield Strength (solid mark) and Vickers Hardness (open mark) as a function of d-1/2 (d : grain size).

[Published in Materials Transactions, Vol. 63 (2022), pp. 872–876]

Relation between stress amplitude (σa) and number of cycles to failure (N) for the un-treated and electroless Ni-P plated specimens.

[Published in Journal of Alloys and Compounds Vol.917 (2022), 165376]

Distribution of different textures: a) Sintered pure Al, b) Hot-rolled pure Al, c) Sintered Csf/Al, d) Hot-rolled Csf/Al, e) Sintered Cu-Csf/Al, f) Hot-rolled Cu-Csf/Al.

[Published in Materials Letters Vol.320 (2022), 132386]

(a) is a variation of Al2O3/Al composite tensile strength and elongation with increasing ARB cycles, and SEM pictures showing the fractography of Al2O3/Al composites processed by (b) 8, (c) 14, and (d) 18 ARB cycles.

[Published in ACS Applied Materials & Interfaces, Vol. 13 (2021), pp. 45089–45096]

[Published in Journal of Materials Science, Vol. 56 (2021), pp. 8679–8688]

Schematic illustrations of upscaling CHPT process for multi-wires

[Published in Journal of Japan Society of Shot Peening Technology, Vol. 34 (2022), pp. 9–14]

Reduction of surface roughness and introduction of compressive residual stress by SP construction were effective to improve the fatigue strength.

[Published in Materials Today Communications, Vol. 27 (2021), 102319]

[Published in KEIKINZOKU, Vol. 72 (2022), pp. 411–419]

https://www.jstage.jst.go.jp/article/jilm/72/7/72_720702/_article/-char/en

3D perspective view of Al7Cu2Fe particles, Mg2Si particles and voids captured at the εa of 4.2% in high-hydrogen Al-Zn-Mg-Cu alloy using synchrotron X-ray nano tomography.

[Published in Metals, Vol. 12 (2022), 2]

The β”-eye was formed on the layered vacancy–solute complex from a solid solution of Al-Mg-Si alloys during first-principles-based Monte Carlo simulations.

[Published in Defect and Diffusion Forum, Vol. 414 (2022), pp. 179–184]

[Published in Materials & Design, Vol. 213 (2022), 110344]

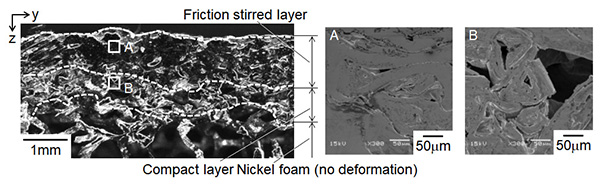

Distributions of tensile strength obtained using microscale tensile test as a function of distance from the tool center for the steel/aluminum alloy interface.

[Published in Bouseikanri, Vol. 65 (2021), pp. 91–97]

EPMA analysis results of high-Ca type Al-Mg-Ca thermal spray coating at a 5 mm wide damage of the exposure specimen after 11 months exposure.

[Published in Materials Transactions, Vol. 63, (2022), pp. 489–496]

In-situ observation of microstructural evolution of 10MoA due to rapid lamp heating. Acicular martensite appeared within 2 s after the start of heating, indicating that martensite is formed during heating rather than cooling.

[Published in Metals, Vol. 11(2021), 1979]

[Published in Materials Transactions, Vol. 63 (2022), pp. 948–956]

[Published in Materials Transactions, Vol. 62 (2021), pp. 1414–1419]

Fig. HRTEM image, taken with B = [01-11]α, of the α/C14 lamellar interface for the 723 K/1 h-aged α-Mg/C14-Mg2Ca eutectic alloy crept at 473 K under a stress of 40 MPa, where the creep test was interrupted at a strain of 1.3%.

[Published in Metals, Vol. 11 (2021), 1913]

Fig. Plots of minimum creep rate vs. lamellar spacing for the α-Mg/C14-Mg2Ca eutectic alloy, where the creep tests were carried out at 473 K under a stress of 40 MPa.

[Published in Journal of Magnesium and Alloys Vol. 10, No.3 (2022), pp. 730–742]

Continuous observation of microstructure during locally heated dieless drawing.

[Published in Materials Today Communications, Vol. 31 (2022), 103344]

(Left) STEM images of heat treated and hot extruded Mg-Zn-Gd alloys containing solute-enriched stacking faults (SESF).

(Right) Asymmetric XRD peak profiles originating from intergrowth-like precipitations of SESF.

[Published in ECS J. of Solid State Sci. and Technol., Vol. 11 (2022), p. 013001]

Ideally ordered anodic porous alumina with an interhole distance of 1 µm prepared by the present process.

[Published in Journal of Materials Processing Technology, Vol. 294 (2021), pp. 117116]

Schematic drawings of computational domain and simulated temperature distribution during conventional and ultrasonic DC casting process.

[Published in Transactions on GIGAKU, Vol. 8 No.1 (2021), pp. 08003–1–08003–6]

A inverse pole figure map and (0001) pole map are shown. Average crystal grain size of extruded material was 136.7 [µm], and the average crystal grain size of the forged material was 42.5 [µm].

Microstructure observation of AlCrN and Nitriding dies by EBSD (Extrusion conditions: billet temperature 450 °C, ram speed 1.0 mm/s).

[Published in Journal of Materials Engineering and Performance, (2022)]

Interfacial microstructure of explosively welded magnesium/aluminum alloy cladding plates.

[Published in Journal of The Japan Institute of Light Metals, Vol. 71, No. 12 (2021), pp 539–548]

https://www.jstage.jst.go.jp/article/jilm/71/12/71_711203/_article/-char/en

Main and cross interdiffusion coefficients (a)  , (b)

, (b)  , (c)

, (c)  and (d)

and (d)  in ternary Ti-Al-Zr alloys at 1473 K.

in ternary Ti-Al-Zr alloys at 1473 K.

[Published in Materials Transactions, Vol. 62 (2021), pp. 1151–1159]

[Published in Corrosion Science, Vol. 200 (2022), 110222]

Left: Box plots of polarization resistance (Rp) for the initial 4 weeks in medium. Right: Schematic illustration of corrosion mechanisms of CAp- and HAp-coated WE43 in medium.

[Published in Corrosion Communications, Vol. 5 (2022), pp. 39–48]

Fig. XPS wide scan spectra of specimens surface after immersed in the solutions for 7 d at 25°C.

[Published in J. Japan Inst. Met. Mater. Vol. 85, No. 1 (2021), pp. 7–16]

https://www.jstage.jst.go.jp/article/jinstmet/85/1/85_JD202002/_article/-char/en

Nano-hardness around grain boundaries at aging temperature of 180°C ; (a) at under-aged around HAGB, (b) at peak-aged around HAGB, (c) at under-aged around LAGB, (d) at peak-aged around LAGB.

[Published in Fluid Mechanics and Thermal Sciences, Vol. 96(2022), pp. 127–136]

XRD patterns of TNTZ subjected to thermal oxidation processing at a temperature of 723K for 40, 50, and 60s.

[Published in Journal of The Japan Institute of Light Metals, Vol. 72, No. 7 (2022), pp. 420–426]

https://www.jstage.jst.go.jp/article/jilm/72/7/72_720703/_article/-char/en

Orientation distribution function (ODF) at the section of φ2=0° for (a) Specimen before forging, (b) Specimen forged by four times at a true strain of 0.18, (c) Specimen forged by four times at a true strain of 0.18, (d) main reference orientations.

[Published in JOURNAL OF MAGNESIUM AND ALLOYS 9 (2021), pp. 130–143]

Distribution of the extreme inverse FIP per aggregate for (a) Mg99.2Zn0.2Y0.6, (b) Mg97Zn1Y2 and (c) Mg89Zn4Y7 alloy at different stress amplitudes.

[Published in Materials Transactions, vol. 62 (2021) pp. 1673–1676]

Reconstructed tomography of (a) absorption coefficient (b) Zn concentration from absorption coefficient (c) absolute integrated intensity (d) volume fraction of GP zones (e) calculated UTS distribution.

[Published in Materials Transactions, Vol. 62 (2021), pp. 1401–1406]

Microstructure of the magnesium target near the crater impacted at room temperature, (a) observed image with SEM, (b-e) IPF (left) and GOS (right) maps in the square portions indicated in (a).

[Published in Titanium, Vol. 69 (2021), pp. 53–59]

A novel titanium-powder-production process based on the shuttle of disproportionation reaction and its backward reaction of titanium ions in molten salt.

[Published in Computational Materials Science 203 (2022) 111081]

Energy landscape of dislocation motion indicating minimum energy paths including the energy differences for the three core configurations and the energy barriers for motion of three cores in their planes.

[Published in Materials Transactions, Vol. 63 (2022), pp. 141–147]

Variation of lattice parameters as a function of milling time for the specimens fabricated via intermittent MA and continuous MA.

[Published in Journal of The Japan Institute of Light Metals, Vol. 71, No. 12 (2021), pp. 555–559]

https://www.jstage.jst.go.jp/article/jilm/71/12/71_711205/_article/-char/en

Precipitates at dislocations or apart from dislocation in HRTEM images of T8 sample aged for 10.8 ks.

[Published in Materials Science and Engineering: A, Vol. 820 (2021), pp. 141557]

Pre-deformation hinders the first hardening but promotes the second hardening until peak. Two types of S phases were observed to form along a dislocation line.

[Published in Metals, Vol. 11 (2021), pp. 1735]

The CS sample has excellent mechanical properties. The direct evidence of Cu aggregation on an edge dislocation was observed.

[Published in Journal of Alloys and Compounds, Vol. 911 (2022), pp. 165070]

Cyclic deformation leads to a significant strengthening effect on Al-Mg-Cu alloys due to clusters and dislocations. The mechanical properties are further enhanced by the combination of cyclic deformation and aging.

[Published in Additive Manufacturing Letters Vol. 1 (2021) 100008]

Simultaneous strength-ductility enhancement of L-PBF processed Al-12%Si alloy due to the homogeneously distributed nanoscale Si precipitates for enhancing the strain hardening.

[Published in Scripta Materialia Vol. 213 (2022), 114635]

Negative strain rate sensitivity of strength of the L-PBF processed Al-12%Si alloy due to dynamic precipitation at ambient temperature.

[Published in Electrochimica Acta, Vol. 399 (2021), 139440]